Tag: IMPs

Metal Panel Roof Restoration & Installation

How to Avoid Common IMP Installation Mistakes

Insulated metal panels (IMPs) are ideal for many roofing and wall applications. They are considered a top-of-the-line choice known for their superior insulation value, high performance air barrier, design flexibility, and fast installation. The simplicity of installation creates a high-performance building envelope. The many design options provide a versatile building solution for commercial, industrial, and institutional projects.

Sounds great, doesn’t it? What’s the catch? Well, those benefits won’t mean much if proper care is not taken during the installation process to ensure you’re getting what you paid for. Potential consequences can span the gamut—from minor aesthetic headaches to extremely costly errors such as leaks and structural issues.

Here are some ways to avoid common pitfalls when installing IMP panels on your next metal wall or roof project.

1. Pay attention to the manufacturer’s product installation manuals.

Installation manuals are not just for show! Even the most experienced installer should read, review and understand the installation guide before installing IMPs, and the panels should always be installed in accordance with the project’s installation drawings.

Don’t simply rely on the “what-you’ve-done-before” mindset. Take the time to review the specifics for every individual project. In addition to providing the information needed to execute a successful install, it can also give installers an opportunity to build upon their own knowledge base. One of the most common errors is related to proper receipt and handling of the panels. Investing a few minutes before the project starts and at the start of each day to review key topics helps avoid costly errors and improves production.

If you have a question or something does not seem right stop and call the manufacturer. It is always best to address a problem up front than try and fix a problem after the building is in operation.

2. Equipment check. Do you have what you need?

To keep your IMP installation on track, it’s imperative to ensure you have the equipment you’ll need for the job. Does your project need one or two forklifts, is a crane a better option? Will your project include longer-length IMPs being installed in a vertical orientation? If so, you may need special lifting equipment so as not to damage the panels. Whatever the details, crews need to be prepared to receive a project’s specific materials on site. A little advance planning will ultimately save you time and money by reducing labor and avoiding costly mistakes.

3. Don’t assume every IMP application is the same.

All buildings are not created equal. Just because a construction crew has had experience installing insulated metal panels on past jobs, doesn’t mean they can assume the process will be exactly the same every time. There will always be specific conditions and variables that need to be taken into consideration. Techniques used for vertical industrial panels will be different for horizontal architectural panels.

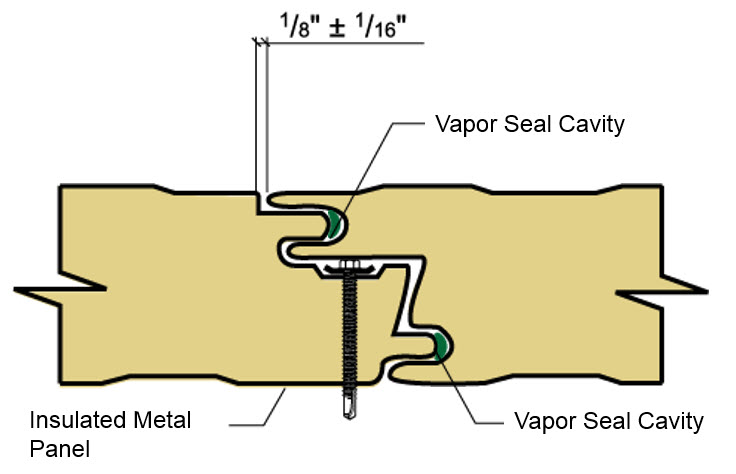

The vapor barrier (a key function of an IMP) is a great example of how a miscalculation can be problematic. Depending on the panel, the vapor barrier may be applied either at the factory or at the jobsite. If the project calls for a cold storage environment, the “warm” side of the vapor barrier will be on the exterior. Alternatively, a commercial or industrial application generally calls for the vapor seal to be on the opposite side of the panel. Confuse placement of the seal and you’re bound to run into problems down the road.

4. Be on the lookout for creases, buckles and framing alignment.

A crease or buckle on the face of a panel might seem like no big deal, but that couldn’t be further from the truth. In fact, framing alignment is one of the most critical aspects to ensure a proper fit-up of the construction as a whole. In terms of the panels themselves, not only will a framing misalignment not LOOK right but can also cause numerous efficiency and performance issues. Installing inexpensive shims can avoid panels needing to be replaced.

Additionally, make sure the first panel is plum and square, if you start right it is much easier to finish right.

Purlins must be level and square and all framing and bracing should be installed before installing panels. (The IMP manufacturer should specify the amount of tolerances allowed.) Also, take care with caulking and taping, foam-to-foam connections (in order to mitigate potential vapor leaks), seaming, and lap joints.

Attention to detail will avoid costly mistakes.

5. Always think ahead.

Being proactive may be the most important piece of advice construction crews need to hear.

For one, be sure to have a panel surplus on hand. You may be of the mindset that ordering extra panels is at worst a waste or at best, not worth the effort. This is a common judgement error that often leads to installation delays. If a crew has only ordered the exact number of panels needed for a job and there is any damage to the product, whether prior to delivery, on-site or during the installation, there a risk to the project schedule. Waiting on replacement panels can wreak havoc on schedules, especially with panels that may need special manufacturing due to custom components, finishes or colors. What do you do with extra panels you don’t need on the initial installation? Building owners can hold on to any surplus panels to be used as replacements, as needed, over the lifecycle of the building. A little preparation today can go a long way.

Other best practices include understanding the project’s site conditions and ensuring crews remain crews up to date on proper installation techniques—including staying current with training and certifications.

By taking this advice to heart, you can exponentially increase your ability to enjoy the many benefits of IMPs and be confident in your investment. For more information on MBCI’s insulated metal panels and proper installation guidelines, we encourage you to contact your local MBCI representative or visit our website.

Insulation Considerations for Metal Building Projects

Once you’ve set your sights on metal panels for your next building project, insulation will be one of the first, and most important, considerations. There are so many variables, though, so how do you know what’s best?

When you’re trying to make a determination of the insulation type, you should first identify what’s driving your decision making. Are your insulation requirements based on external parameters, such as job specs or established code requirements, or is there some other self-proposed condition at play like the end-use function of your building? Do you require upfront cost savings or is long-term value what you’re after?

Here we’ll take a look at some of the most common determining factors and how they might affect your insulation choices.

Energy Codes

Depending on whether you’re building in the commercial or residential arena, and what the physical location of your project is, you may have to adhere to strict energy/building codes that will be an unmovable goal post in your decision making.

Are there any local code or project-specific stipulations as far as minimum R-values for the roof or for the walls? What must you be in compliance with? There can be many different aspects of an energy or building code that you will need to research. For example, there may be an envelope solution where the whole building nets out “X” R-value. Or, a prescribed method could be mandated, where each individual component (i.e., windows, doors, walls, etc.) going into that building cannot exceed (or must meet) a particular requirement.

Let’s say, as an example, you have a code that requires you to have a continuous R-value at your structural attachment point. Depending on what that requirement is, it may be harder to achieve that by using a rolled or batt fiberglass systems. You might be able to achieve it much more easily with a componentized system using metal decking/liner and rigid board insulation, or perhaps an insulated metal panel (IMP) may be better suited. In that case, you could be looking at spending more money for that panel system while saving money on the labor … which brings us to the next variable: upfront costs.

Upfront Costs

Another critical factor is the cost associated with materials and labor of the system you’re going to install. Let’s say, for instance, your needs require a higher-end type installation in order to reach higher R-values or a code-prescribed method. How are you planning to achieve that?

In some instances, you may be looking toward an insulated panel system, which can readily give you those higher installed R-values. While these are extremely efficient systems, there can be a notable bump in the panel material price to get to that same level than if you choose a single-skin approach with a fiberglass or rigid board insulation system. You would, therefore, need to accurately compare the installed costs of the two systems versus just the material alone. Which will be less expensive/more efficient: the multiple components with lower individual costs plus more labor time and expense to assemble OR the potentially higher individual IMP panel price but with less time and expense to install? You will need to look at the project holistically to determine which is more cost-efficient for the specific situation.

Long-term costs, value and end-use functionality

Oftentimes, upfront material and labor costs need to be evaluated in terms of potential long-term savings and value. Some things to consider here are what your big picture needs are for the structure, including an assessment of how it will be used now and in the future. Unlike with dictated codes and regulations, here it may be more a question of wants vs. needs or owner-occupying vs. vendor leasing.

While you might want an R-30 building, for instance, is it economically beneficial for your end use of the building? Let’s use this example: If you’re a homeowner using a metal structure to store relatively non-valuable belongings, how well does it have to be insulated? Is it worth a high price point? In this case, perhaps single layer roof and wall insulation will be adequate for your needs.

If on the other hand, you’re a builder contracted to construct a structure for which interior climate control is critical for the end use—either because of the production to occur inside or perhaps due to food storage or other temperature-sensitive contents—then you might lean more toward an insulated panel system. In another example, if there’s going to be the potential for an abundance of heat or moisture in the building, as with paper products production or wastewater treatment, then you’ll want to be certain that the insulation system you use best resists such an interior climate and doesn’t permit condensation to form. In this example, it is critical that the structure is significantly protected so that moisture cannot become trapped in the roof or wall assemblies leading to reduced building efficiency or even formation of mold.

You should also consider how long it will take to recoup your initial investment. Obviously, for instance, you may spend less money upfront by only putting 4-inch blanket in your single layer metal walls as opposed to choosing to install an insulated metal panel (IMP) system, but long-term, is the money you save by going with the lesser insulation system going to be more than what the energy savings would be over the time that you’re the occupant of the building?

If you’re only going to be in the building for one or two years, or you’re not even occupying the building, you might be tempted to install a lesser expensive system, but then you might be risking not being able to retain tenants or impacting future resale value.

What Are the Insulation Options?

Once you’ve identified what the driving factors are for your insulation system choice, you can match up your needs with most popular options, which are:

Fiberglass insulation solutions, including over-the-purlin systems; cavity fill insulation systems; batt insulation; rigid board insulation via a composite system with metal decking and vapor barrier; or spray-on insulation systems. Alternatively, if a foam core insulation is preferred, it may be worth considering the use of insulated metal panels (IMPs) that are designed, engineered, and fabricated to be compatible with metal building construction as an envelope building solution.

For more specifics on the types of insulation systems that are available, check out this MBCI blog article: https://www.mbci.com/coordinating-roof-insulation-with-metal-building-construction/

Design and Performance Benefits of Insulated Metal Panels

In a prior post on insulated metal panels (IMPs) we reviewed some of the basic things everyone should know about this versatile and lightweight metal building component. In this posting, we will drill down a bit more on the benefits of incorporating IMPs into a new or retrofit construction project. Here are some of the top reasons they are so popularly used in both walls and roofs:

Energy Conserving, Space Saving Insulation

Foam plastic insulation is used between the metal skins of IMPs. Such insulation has been accepted for use by building codes for quite awhile provided it meets certain conditions. IMPs have been tested and shown to meet or exceed all code requirements for construction and for energy conservation too. Part of their appeal over other ways to insulate is that they can achieve high performance in a thinner wall or roof assembly than would be required with other types of insulation, such as fiberglass. IMPs are available in thicknesses that range from 2 to 6 inches and have corresponding R-values from R-14 to R-46 allowing design professionals to select the thickness that matches the energy performance level sought in a particular building. Other insulation types would require thicknesses of at least twice as much to approach the same R-values as IMPs. Further, the metal interior and exterior skins are the only finish material needed so the total panel thickness is very space efficient. Thinner IMPs in the walls and roofs can save space in the building or on the site all while achieving high energy performance.

Durability, Longevity, and Low Maintenance

The manufactured panels are rigid and quite strong. They have been tested for compression, tensile, and shear strength with impressive numbers that come about because of the combination of the rigid foam and steel properties. The surfaces are made from the same long-lasting galvanized and factory finished steel used in other metal wall and roof panels so their resistance to weather, abuse, and even harsh conditions has been proven, making them very easy to maintain. In locations where severe weather and storms are a concern, they can also be specified to meet requirements for heavy winds, hail, and similar concerns. Plus, since the skins of the IMPs are made of noncombustible steel, they provide an ignition barrier as part of an overall fire protection scheme for the building.

Cost Saving Construction

IMPs are an “all-in-one” product that takes the place of many other products and components used in traditional construction. Instead of requiring multiple trades and materials to be installed individually over some number of weeks, IMPs are installed by a metal building contractor and allow the walls and roof to be completely closed in with a single trade. The use of concealed fasteners in the side joint of the panels makes installation quick and easy. Unlike other construction systems, the inherent strength and resiliency of IMPs means that work doesn’t need to stop over weather concerns. All of this saves a considerable amount of labor costs and can also save a lot of time meaning buildings can be completed quicker and more economically. It could also mean that an owner is able to occupy and use the building sooner, thus reducing construction financing costs and allowing operations to begin more quickly.

Versatility for Use in Many Building Types

IMPs can be used in virtually any type of new construction and for many retrofit applications too. There is a range of modular panel sizes that can work successfully with different structural elements of the rest of the building. The finished profiles and colors can all be selected to match the design needs of the building with edges, corners, and trim details all based on simple, appealing aesthetics. There are even IMPs specially designed for cold storage or refrigerated space applications. These panels may be part of the building exterior or create an isolated space within a larger building. Either way, they are designed for the rigors of a high use installation.

With such a broad range of benefits and capabilities, you owe it to yourself to check them out for a building project that you may be involved in. The best place to start is by contacting your local MBCI representative, and by signing up for our newsletter to subscribe to our blog.

What You Need to Know About Insulated Metal Panels

Insulated metal panels (IMPs) are “lightweight, composite exterior wall and roof panels with metal skins and an insulating foam core” as defined by the Metal Construction Association (MCA). The outer skin serves as either metal wall siding or metal roofing using standard profiles, while the inner face serves as a metal interior finish or liner. The rigid insulation between the metal skins gives the panels their superior energy conservation properties and also provides a rigid core for extensive spanning capabilities across structural members.

With this basic make-up in mind, here are a few things you should know about using IMPs in a metal building project:

Building Types

Virtually any building being designed as a metal building should consider the use of IMPs. This includes all types of commercial, industrial, institutional, recreational and government buildings. More specifically, IMPs have been used very successfully on manufacturing facilities, schools, retail centers, offices, warehouses, power plants and many other building types.

Insulated Roofing and Walls Assemblies

IMPs serve as a complete wall or roof assembly. That means they can provide cladding, insulation, a water-resistant barrier, an air barrier, and finished surfaces all in one panelized product – essentially everything but the building structure upon which they are installed. These characteristics are true for conventional buildings as well as for specialty construction types such as the climate controlled processing, storage, or distribution of perishable food or other items. With panel thicknesses commonly available from 3 inches to 6 inches, walls and roofs can be designed to meet the specific thermal performance requirements of virtually any building need.

Architectural Design

IMPs are available in a wide variety of colors, widths, profiles and finishes, enabling virtually any aesthetic desired for walls and roofs. Further, architectural IMPs provide the freedom to address building-specific or unique circumstances with options such as custom shapes and widths, special custom colors and finishes, custom fabrication including, but not limited to bent corners, curved panels, and trimless ends. Architectural IMPs also offer options to integrate with windows, louvers, sunshades or other similar products to offer total building envelope solutions.

Panel Joints

Most IMPs are fabricated with the intention of working together as a complete system. That means attention has been paid to the design of the edges so the panels can interlock and be sealed to form a continuous joint that is water tight and air tight. In some cases panels may need to overlap, such as on long roof runs over 50 feet, but manufacturers have worked out those details to help assure the roof or wall performs as intended. Based on this, properly-installed IMP systems generally come with a very long warranty period.

Ease of Installation

The fact that IMPs are a single, finished, rigid panel, makes them quicker to install than other multi-product and multi-step assemblies. This translates to obvious labor savings and some material cost savings compared to other systems. Further, the simplified installation process has been shown to limit exposure to accidents, helping create a safer, more efficient work flow. It can also mean that construction time schedules are easier to meet or even beat.

To find out more about IMPs and ways to use their full characteristics and capabilities on a building you are working on, contact your local MBCI representative.

Sealing the Deal: The Importance of Properly Sealing the Building Envelope Using IMPs and Single-Skin Panels

The primary purpose of a building’s envelope (roof and walls) is to protect the building’s interior spaces from the exterior environment and provide the desired exterior aesthetics. Whether choosing insulated metal panels (IMPs) for their superior performance or, instead, looking to the wide range of aesthetic choices available with single-skin panels—or some combination of the two—the common goal must always be to protect the building from the potential ravages of water, air, vapor, and thermal/heat. By ensuring proper installation of metal panels and, thereby, properly sealing the building envelope, problems can be mitigated, efficiencies maximized, and the integrity of the building protected.

Here, we’ll briefly consider the benefits of each panel, and some key considerations relative to their sealant needs and capabilities.

Insulated Metal Panels (IMPs)

IMPs are lightweight, composite exterior wall and roof panels that have metal skins and an insulating foam core. They have superior insulating properties, excellent spanning capabilities, and shorter installation time and cost savings due to the all-in-one insulation and cladding. In effect, IMPs serve as an all-in-one air and water barrier, and are an excellent option for retrofits and new construction. With their continuous insulation, roof and wall IMPs provide performance and durability, as well as many aesthetic benefits.

Generally speaking, because of the nature of the joinery, it is easier to get a good seal in place with IMPs given their relative simplicity (i.e., putting the two pieces together with the sealant). They require great attention, though, in terms of air and vapor sealing—aspects largely controlled by the installers on a given project. As an example, vapor sealing in cold climates or applications is critical to the overall soundness of a building. Consider the damage a building could incur if moisture seeps into a panel and becomes trapped; it if freezes, it could push panels out of alignment. This would result in not just an unattractive aesthetic, but a performance failure as well. In order to be effective, all sealant and caulking must be fully continuous.

Single-Skin Panels

Single-skin panels, alternatively, offer the advantage of an expansive array of colors, textures and profiles. They are also thought to have more “sophisticated” aesthetics than IMPs. Single-skin panels are available in both concealed fastener and exposed fastener varieties, and are part of an assembly. They can be used alone or in combination with IMPs, and as long as the needed insulation is incorporated, single-skin panels can meet technical and code requirements, depending on the application. Single-skin products offer a wide range of metal roof systems and wall systems as well.

Getting the proper seal on single-skin panels may require extra sealants or closures, and have more parts and pieces that have to come together to create the seal. However, when properly installed and sealed, they can provide excellent performance in their own right. Some key caveats include ensuring panel laps are properly sealed with either tape or gun butyl sealants, and carefully inspecting air and water barriers for proper installation as well as penetrations through the wall for sealing/fire caulking prior to panel.

In most cases, following the details for the most common conditions will give you a successful and high-performing outcome.

Regardless of the type of metal panel used, taking the time and effort to ensure the sealing and caulking details are properly handled, metal buildings can protect the built environment and provide long-lasting quality and performance.

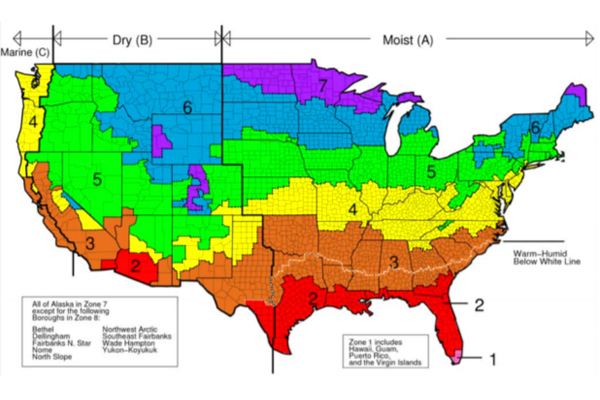

How Energy Codes Influence Metal Roof Panel Selection

On a very basic level, specifiers can look at a climate zone map and get an idea of the metal roof panel best suited to a specific geographic region. The issue, however, is actually much more complex. One must know that overlooking any detail could result, not only in less-than-ideal performance, but also in costly project fail, often related to the project not meeting required energy codes or other standards. With this in mind, an important initial question to consider is how to select metal roof panels that conform to new and fast-changing energy codes and their designated climate zones.

To begin making wise considerations, the architect must know what codes are in play. For instance, is it IECC or ASHRAE 90.1? Which year of the code/standard? Are there additional local code requirements? Even if a state adopts a particular energy code, it doesn’t necessarily mean that all jurisdictions will adopt the code at the same time. Along with this, some local jurisdictions may have their own or additional requirements. To be successful, it is imperative to know what the regional project goals and requirements are. This will require research prior to specifying the metal roof panel and its assembly.

Using IECC and ASHRAE 90.1 for Energy Code Compliance

Three of the basic metal building roof panel types are single-skin standing seam, screw-down and insulated metal panels (IMPs). When using the tables in IECC and ASHRAE 90.1 for metal building roofs it must be remembered that these tables are based on single-skin standing seam roof panels and purlins that are 5′ on center. The tables provide the required R-values and/or U-factors based on climate zones, along with other assembly requirements noted with each tables. In the Appendix of some versions of ASHRAE 90.1, there are allowances for modified roof assemblies, including screw-down metal roofs.

Often, in certain climate zones, the required R-values and U-factors may be so stringent that the logical first consideration is to use insulated metal panels. IMPs are a great choice for offering high insulation properties in a top-of-the-line product and the R-values and U-factors are readily available for use in compliance calculations.

Keep in mind when deviating from the prescribed assemblies in IECC and ASHRAE 90.1, calculations will be required to show compliance, along with modeling and/or the use of approved compliance software, such as COMcheck.

Making Informed Decisions

Selecting the right metal roof panel is an important step to achieving energy code compliance. Even though energy codes can be complex and are constantly evolving, by making informed metal roof panel selections you will add to the overall success of your project.

Top Five Tips:

- Know your code. Find out what energy code is required for your project.

- Know your zone. Requirements vary by climate zone. Identify your project’s climate zone.

- Understand your options. Deviating from specified assemblies will require approved proof of compliance.

- Choose wisely. Research the properties and assembly requirements of any metal roof panel. Use this information in conjunction with energy code requirements to make wise choices.

- Call with questions. Call the manufacturer with questions before you get too far down the road.

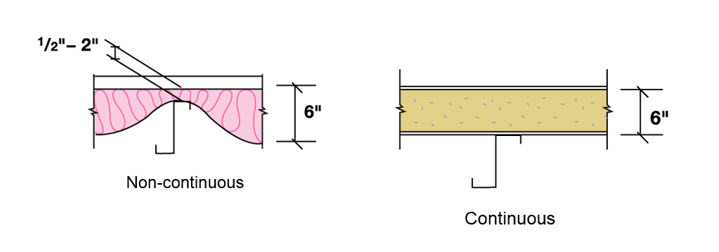

Combatting Thermal Bridging with Insulated Metal Panels

When using compressible insulation, say for instance fiberglass batt, consideration must be given to how that insulation is going to be deployed in the actual wall or roof. For instance, installers might place the insulation across the framing members and then smash it down with the cladding and run a screw through to the underlying structure. The problem here is that the insulation is rated with some R-value—and that R-value is determined by an ASTM procedure that also determines what its tested density is. So in essence, it’s ‘fluffy’ insulation.

One manufacturer’s insulation, however, might be thicker than another’s. The contractor is buying an R-value, not a density or a thickness. The insulation is tested to that R-value at whatever thickness and density¹ is needed to achieve it. Let’s say R-19 fiberglass batt is specified, but then it is put in an assembly and smashed down flat… now it’s not R-19 anymore; it’s now R-something else. That’s a thermal bridge—when the insulation’s R-value has been compromised.

Unfortunately, thermal bridging is almost impossible to eliminate. In the example above, another choice might be to put it between studs. Except in this situation, the studs break the insulation. While it’s not pinched, the studs are separating it. Whether the studs are metal or wood, in either case it’s still a significant thermal short circuit or a thermal bridge.

Even with the highest quality insulation systems—insulated metal panels, for example—a joint is required. Building is not possible without putting neighboring panels together. Therefore, insulation is discontinuous. While it’s impossible to avoid thermal bridging, there are two requirements to ensure the building performs the way it needs to perform.

- Thermal bridging must be mitigated. In other words, the designer or installer has to try to eliminate as much of it as possible.

- If thermal bridging is unavoidable, it must be accounted for in some fashion, which usually means putting more insulation somewhere to make up the difference. This is called a “trade-off” and is allowed by most building energy efficiency codes.²

Why Insulated Metal Panels?

Insulated metal panels then are the best bet, because although the joint is a thermal bridge, in effect, it is not nearly as impactful as breaking a line of fiberglass with a stud or smashing the fiberglass between the panel and a framing member. In the illustration below, R-value doesn’t just vary at that point where the panel and the stud meet. The entire insulation line gets smashed and one would have to go some distance from the stud before the insulation returns to its normal, fluffy thickness. These issues need to be mitigated and accounted for.

Manufacturers such as MBCI and Metl-Span publish insulated metal panels as U-factors because the joint is tested as part of the assembly (both mitigating and accounting for the aforementioned issues). These values can be found on product data sheets and technical bulletins, such as Metl-Span’s Insulation Values technical bulletin, published January 2017.

References

- ASTM C 665 – 12, Standard Specification for Mineral-Fiber Blanket Thermal Insulation for Light Frame Construction and Manufactured Housing, Table 1, Footnote c.

- ASHRAE 90.1 – 13, Energy Standard for Buildings Except Low-Ride Residential Buildings, Section 5.6

- High Performance Green Building Products – INSMP2A (CEU)

Spray Polyurethane Foam (SPF) Insulation on Metal Roof and Wall Panels

With building code compliance and sustainable building envelopes at the forefront in today’s marketplace, spray polyurethane foam insulation (SPF) applied to single skin metal roof and wall panels is an alternative to insulated metal panels with a manufacture-applied polyurethane foam core. SPF insulation improves a building’s energy efficiency and provides thermal, air and vapor barrier capabilities.

What Is Spray Polyurethane Foam (SPF) Insulation?

SPF insulation consists of isocyanate and polyol resin that is chemically combined and applied to surfaces using a spray gun. SPF insulation can be open cell or closed cell. Open-cell foam provides insulation and air sealing for a building, but is water and vapor permeable. Closed-cell foam provides better insulation than open cell and also functions as an air barrier. Closed-cell foam differs from open cell in that it prevents water entry, minimizes moisture vapor permeability and decreases air leakage, making it the preferred insulation to apply to metal panels.

SPF insulation is well suited for use as interior insulation for metal wall and through-fastened metal roof panels. The traditional thermal insulation layer—one or two layers of batt insulation with a facer—has its intricacies; for example, compressed areas and difficulty taping seams at edges and penetrations for air barrier performance. But because of SPF’s inherent physical characteristics and spray application method, SPF overcomes many obstacles.

8 Application and Safety Tips for SPF

Using SPF to fully insulate and seal a building with metal panels can have unintended consequences if the material characteristics and project parameters are not well thought out. The Metal Construction Association (MCA) recently conducted research with the Spray Polyurethane Foam Alliance (SPFA) and published their findings in a technical bulletin. It includes the following best practices and considerations for installing SPF.

- Utilize a certified foam spray technician to ensure the insulation meets the desired thickness, density and adhesion.

- Only apply SPF to clean, dry areas.

- SPF should not be used on standing seam metal roof panels because it may restrict the thermal movement of the panels, causing distortion.

- Follow a “picture frame” application technique, further detailed here, to prevent SPF from getting between girts and metal panels, causing deformation.

- Notify other contractors, including HVAC and electrical, to ensure necessary precautions are made.

- Follow building code requirements for fire protection because in some instances SPF may meet thermal barrier requirements.

- Prevent SPF chemicals from being drawn into a building’s ventilation system during and after installation. There may be a mandated wait time before other occupants can reenter the space.

- Consult with your metal panel manufacturer before applying SPF.

Read more recommendations and findings by the MCA by downloading their technical bulletin, Spray Polyurethane Foam Insulation on Interior Surfaces of Metal Panels, here.