Beauty is More Than Skin-Deep

The most basic requirement of any building is to keep the elements out – while keeping comfortable conditions in. Those elements can be relentless – from bitterly cold wind, snow, sleet and ice to ferocious heat and torrential rain. It’s no wonder buildings have historically been clad in multiple layers to combat these different forces. For centuries, those multiple layers have done the job adequately. But advances in manufacturing, materials and technology have completely changed the game, and you can take advantage of all of it with backup wall systems from MBCI.

A Package Deal

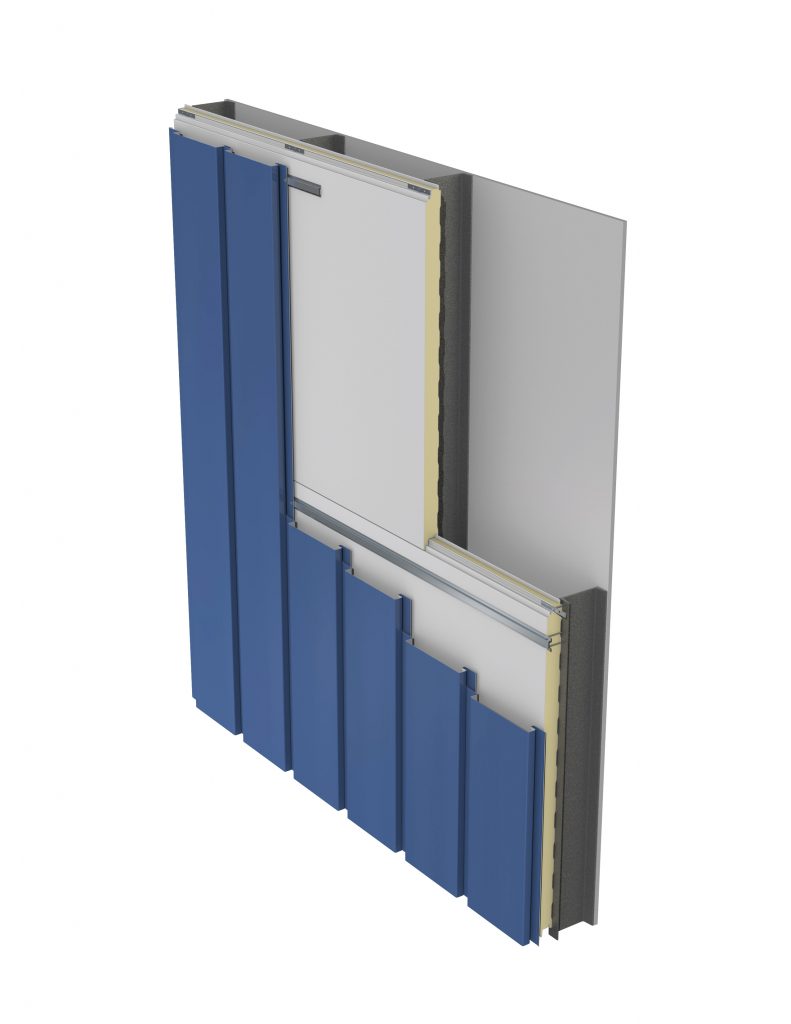

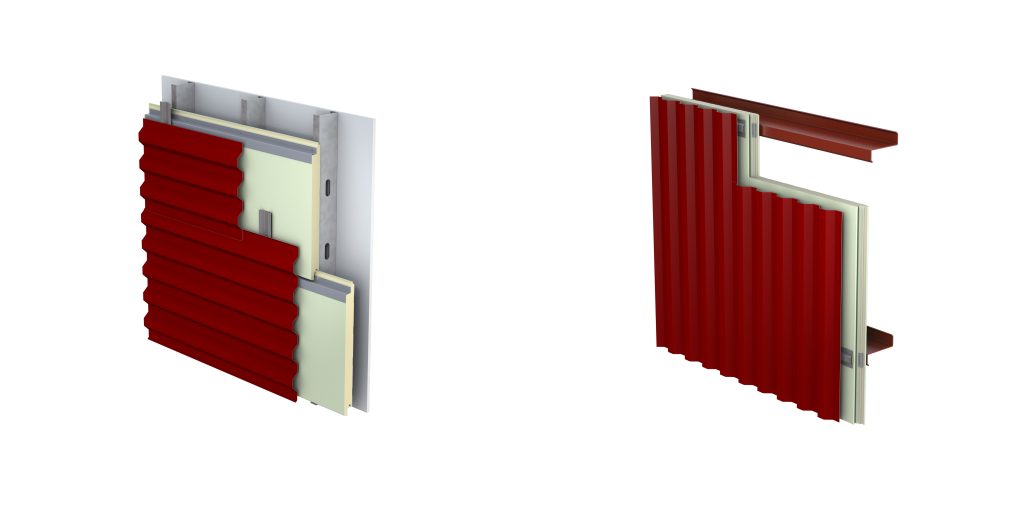

Like insulated metal panels (IMPs), backup walls combine air barrier, vapor barrier, moisture control and insulation into an all-in-one product. The key difference between IMPs and backup walls is that while IMPs function as the rainscreen or façade, MBCI’s backup walls are designed to work with the rainscreen or façade of your choice.

Instead of relying on three or four different contractors to install insulation, Zs, sub girts, air/vapor barriers and sheathing, one worker can install backup walls in one simple step. This has shifted construction standards in cost savings, sustainability and design integrity in ways with which traditional walls simply can’t compete. It’s hard to justify the scheduling and liability hassles of traditional backup wall construction when you could more quickly and reliably weather-in a building with a backup wall system.

Alleviating Headaches

Backup walls eliminate a number of common headaches from the jobsite. There’s no longer a need for multiple crews to work in turn on the cladding, and likewise no need for conventional batt or board insulation, exterior gypsum, air barriers, vapor retarders or building wraps. That’s a sizeable amount of material, subcontractors and coordination suddenly off your plate. Better yet, the expedited close-in/dry-in times mean interior trades can move in and get started sooner.

Façade Freedom

Backup walls are a virtually unbeatable solution for all building types in all climates. MBCI’s Backup Walls are made of foamed-in-place polyisocyanurate with two steel skins, offering strength, durability and a superior drain plane – all in one foolproof, easily installed product. Once the backup walls are installed, you can choose nearly any type of rainscreen or façade you like, from brick and metal to terracotta, ACM and stucco. A popular design choice is an aesthetically pleasing combination of facades. For instance, a public-facing part of a building might be clad in handsome brick or stone, while the obscured sides and rear are clad in IMP’s or something more economical.

Insulation Domination

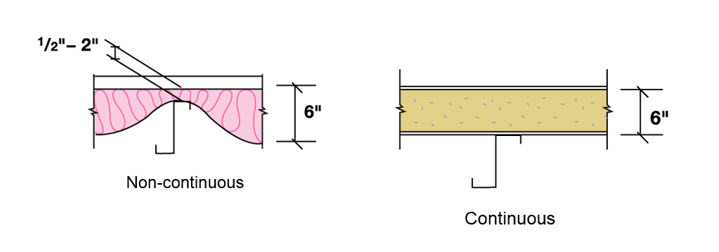

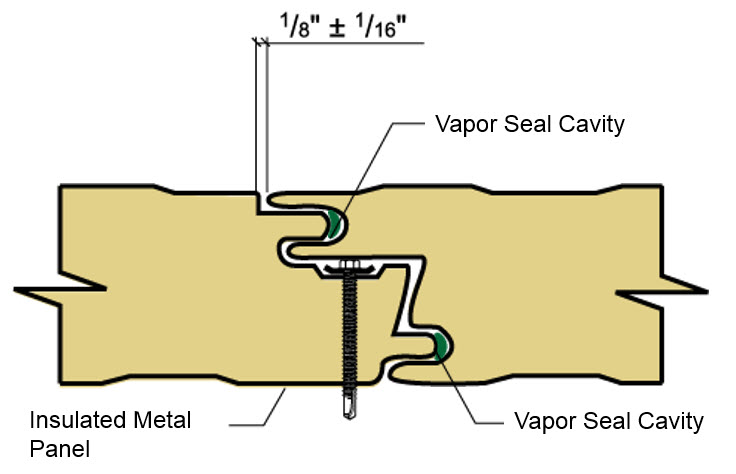

Traditional multi-component walls with continuous insulation require supplemental Z steel framing to convey wind load from the rainscreen to the supports, causing a loss in thermal performance and condensation potential in the cavity. The all-in-one structural construction and enclosed system of backup walls eliminates this problem and makes for better thermal performance. Another often-overlooked concern, air infiltration is addressed in MBCI’s Backup Wall Systems by providing a continuous air barrier via a formed metal liner with a combination of field- and factory-applied sealants. In fact, MBCI’s Backup Walls achieve U-Factors that exceed the International Energy Conservation Code (IECC) energy performance requirements based on tests in accordance with ASTM C1363. They also offer outstanding fire resistance, meeting requirements of the NFPA 285 multi-story fire test.

Making the Right Choice

Depending on your ultimate end-goals for design and practicality, either the BW Universal System™ or the BW Stretch System™ will suit your needs best. BW Universal covers two-foot spans, is installed horizontally, and can accommodate nearly any rainscreen or façade with horizontal or vertical rainscreen rails, panel clips or brick ties. BW Universal is often chosen for more architecturally driven projects due to its compatibility with any façade. The BW Stretch System’s primary differentiating characteristic is its ability to cover up to six-foot spans. BW Stretch is compatible with several rainscreens, though it’s not a good match for masonry.

Though BW Stretch is installed vertically, and BW Universal is installed horizontally, MBCI product manager Jennifer Franz clarified that “Some people think that means the facade can only be installed horizontally or vertically. That is not the case. Either one can have horizontal or vertical facades.” Franz also pointed out that rainscreens and facades often have their own span requirements, which designers should be aware of before making final decisions. “The BW Stretch System can span up to six feet,” she said, “but that doesn’t necessarily mean the rainscreen or façade you put in front of it can. The façade may still dictate a lot of the capabilities of the wall. You need to understand the capabilities of the facade as well as the BW panels.”

Get Started

Whichever system you choose, you’ll receive a weathertight 10-year warranty. But you’ll also receive so much more in terms of time and money saved, hassles avoided, and peace of mind gained. When you’re ready to learn more about MBCI Backup Wall Systems, simply get in touch with your representative. We’ll be happy to help – and you’ll be happy you reached out.