One of the most misunderstood aspects of a metal roofing system is the proper use of a vapor barrier. There are many sources of information about this topic – some of which are based on science, some based on anecdotal field experience, and some based on journalism. Here, we will try to break it down to the basic principles that can be used to understand the latest options for a metal building roof system today.

What is Vapor?

The observed science tells us that water can take three forms, depending on temperature and its ability to interact with other things around it. Water can be a liquid that we drink, solid ice that we can skate on, or a gaseous vapor that is part of the makeup of the air we breathe. We can’t see water vapor in the air but we can feel it – we call that humidity. High humidity means a lot of water vapor is in the air, typically coupled with higher air temperature – and both can make us feel uncomfortable and “sticky.” Low humidity means the air is dryer – more typical in lower-temperature air – but this may also be uncomfortable for our breathing, skin dryness, etc.

Why is Vapor a Concern?

As long as the gaseous water vapor stays in the air at a moderate or comfortable level, there is no real concern. However, since water vapor responds quickly to temperature, it can turn back into water as soon as it encounters a surface that is cold enough for it to make the transformation. We know this phenomenon as condensation, and anyone who has seen a cold drink collect water on the outside of a glass on a humid summer’s day has experienced it. It is the same phenomenon that shows up on the surface of windows in a building when there is a big difference between inside and outside temperatures. We know that the amount of water vapor (i.e., humidity) present and the air temperature can both be variable at any given time, but there is always a predictable point at which water vapor will condense and form water drops – this is called the dew point. When vapor in the air encounters a temperature at or below the dew point, condensation occurs.

What Does This Have to do With Metal Roofing?

Metal roofing systems and condensed moisture are not a good combination. If airborne moisture seeps into a metal roof assembly, finds a cool surface, and condenses on any surface there, it likely won’t be visible from inside or outside of the building. That trapped water can then cause rust and corrosion of metal parts, resulting in real damage. It can also collect and saturate building insulation, rendering it ineffective. If enough water condenses, it can cause visible staining or grow mold, causing concerns for people inside the building.

Do Building Codes Address This?

Absolutely – they require that the building be protected from the possibility of damage caused by water vapor. Since the concern is to restrict the flow of airborne moisture in relatively warm air from reaching a cooler surface to condense on, they call for something to be installed on the “warm” side to prevent that flow. For most buildings across the United States, the warm side is the interior face of the roof and walls. However, if the building is kept cold as in a refrigerated warehouse or storage building, then the warm side is likely on the exterior. The same is true in southern climates where warmer, humid air is the exterior condition and cooler interiors are common.

What is the Best Solution?

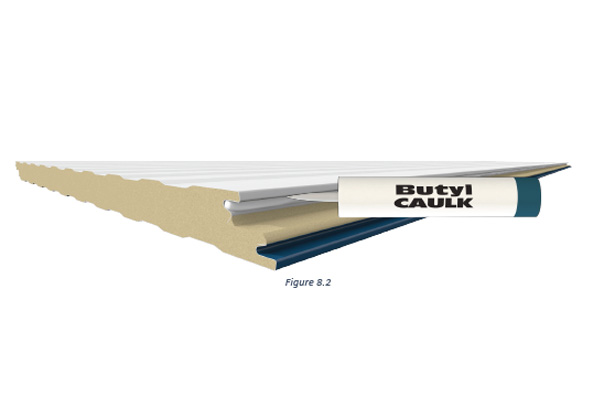

Manufacturers of insulating products have been involved in addressing the best ways to provide not only insulation to keep building temperatures warmer, but also vapor barriers to restrict the flow of airborne moisture. After literally decades of trying different types of vinyl and polyethylene facings over fiberglass insulation, most have realized that those membranes simply don’t provide enough protection to be effective. Instead, most are now offering a choice of laminated facings over the insulation that can be installed so they are exposed to the appropriate warm side of the roofing system. These fairly sophisticated laminations include:

- Polypropylene-scrim-kraft consisting of layers of white or metalized polypropylene, fiberglass reinforcing, and white kraft paper on the order of 11-30 lb. weight

- Polyprolene-scrim-kraft consisting of aluminum foil, fiberglass reinforcing, and 30 lb. kraft paper

- Vinyl-reinforced polyester

All of these latest advancements in vapor barriers can provide comparable, high levels of protection, but their selection can depend on a variety of other building factors. Therefore, it is always best to engage an architect or engineer in the design to review the needs of the entire building to select the most appropriate, specific solution for an given project. It will also be important that all seams, connections, and penetrations of the vapor barrier are addressed in the design and construction, which are similarly best addressed by an architect or engineer to assure there are no breaches in the protection provided by the barrier.

To find out more about vapor barrier and insulation products for metal roofing systems, contact your local MBCI representative.

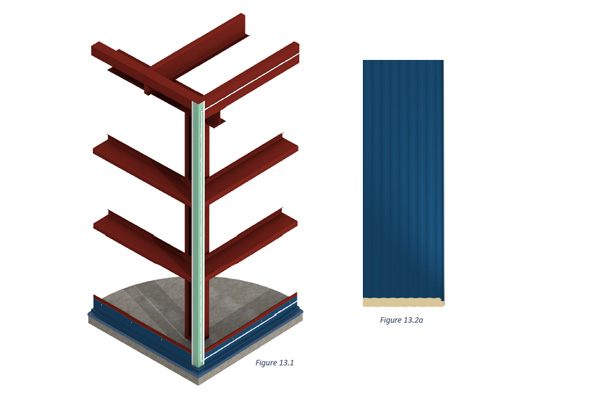

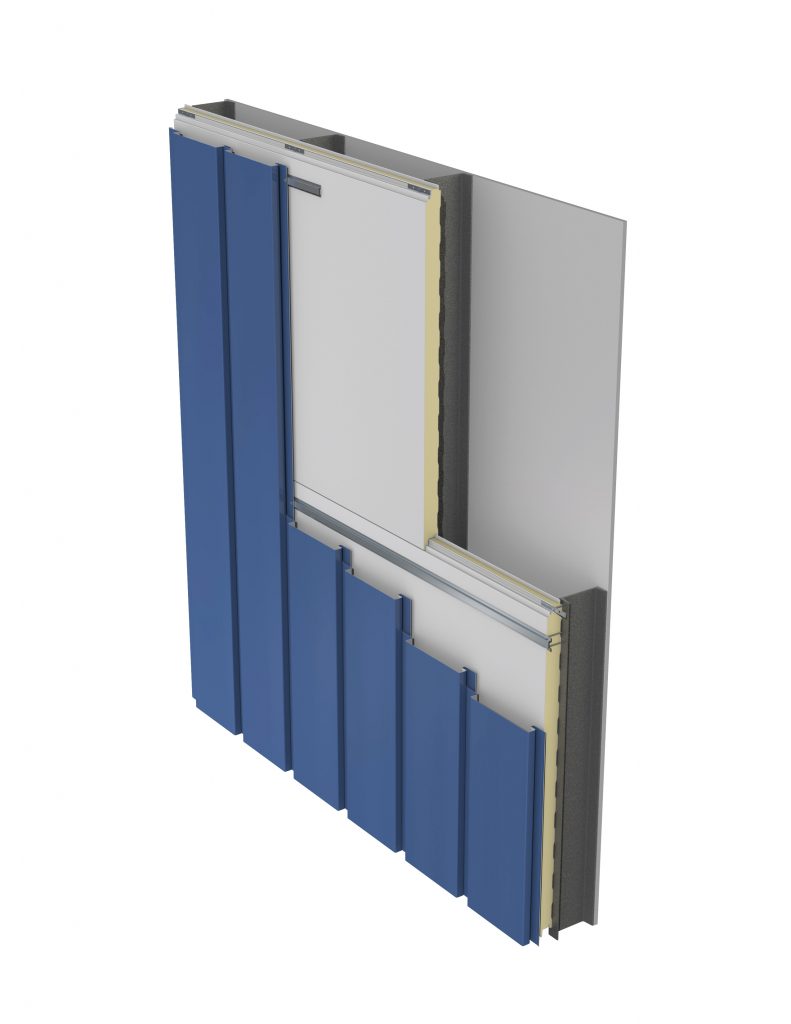

In fact, engineered metal panel systems offer arguably the best possible continuous exterior system. Not only are they properly applied exterior to the building structure—outboard of columns, joists and girts—but they are also designed to ensure an

In fact, engineered metal panel systems offer arguably the best possible continuous exterior system. Not only are they properly applied exterior to the building structure—outboard of columns, joists and girts—but they are also designed to ensure an