Energy codes and increasing energy costs have prompted the installation of more roof insulation into metal buildings in recent years to make them more energy efficient. That is fundamentally a good thing and metal building manufacturers have developed ways to accommodate a variety of building enclosure packages that increase energy performance while still being engineered to meet the structural requirements of the building. This allows the whole building envelope to be designed and fabricated so it works as a complete, coordinated system.

The metal roofing or metal building suppliers typically don’t design the insulation systems. However, it is important to include them in the discussions or make them aware of what type of system is to be installed. It is not uncommon for a metal building to be ordered with the design stipulation of “insulation by others.” In that case, coordination is needed between the person ordering/designing the insulation system and the metal building manufacturer or roofing supplier. Since there are a great many variables in the way that insulation can be provided, it is not appropriate to think that the design of structural systems (purlins and roof bracing) and cladding systems (clips, fasteners, and metal roofing profiles) will necessarily accommodate all the same insulation in all conditions. Rather, unless the specific details of the insulation system being used in the building are communicated effectively at the time of the order, the manufacturer can not assure compatibility of the systems used with the insulation system that is to be installed.

In order to understand some of the variability in the options, let’s look at some of the common ways that metal buildings are or are not insulated.

Uninsulated Roofs:

Buildings that do not have any heat or air conditioning in them may not need for an insulated roof. This could be true for outdoor shelters, some agricultural buildings, or vehicle storage buildings. However, uninsulated metal roofs have the potential for “roof rumble” as they move due to thermal expansion and contraction, wind, or weather as there is no insulation to mask or deaden this noise. Absence of insulation can also lead to condensation during certain times of the year if temporary heat is added to the building. This condensation builds up and can drop or fall onto whatever is below. Many times condensation issues are mistaken for roof leaks when in fact it’s a mechanical design issue of the building envelope that’s not been properly addressed. If neither sound nor potential condensation are a concern, then there’s no problem. But if either or both need to be avoided, then some basic level of insulation may be prudent.

Over the Purlin Systems:

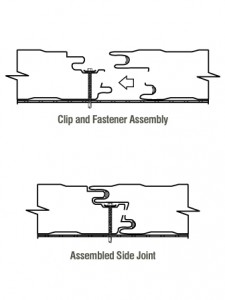

One of the most common insulation systems for metal buildings and/or open framing systems is to simply install rolls of blanket insulation. In this case, fiberglass insulation with a reinforced liner is draped over structural beams and purlins. The rolls are supplied to length by the insulation supplier based upon the roof structural layout and the required “R” value necessary for the building envelope in thicknesses that can vary from 3″ to 12″. Is is this thickness to be installed over open framing that the metal building/roofing supplier must be made aware of. Based on this thickness, the panel profile can be verified to determine if it can be used as well as confirmation of the correct clip heights and screw lengths for installation. Keep in mind that the supplier will offer a guide to the installer based upon insulation thickness. As insulation can vary by manufacturer, it will be up to the installer to make adjustments as needed in the field to ensure proper placement and hold modularity of the steel system. (See Respect the Module: Metal Roofing Panels are Modular for Good Reason)

Cavity Fill Insulation Systems:

When higher “R” values are required for roof insulation, a single layer over the open framing system may not be sufficient. When that occurs, the designers of the building envelope may need to employ the framing cavity to add more insulation. There are also variation on the cavity fill approach.

One means is to simply introduce a second layer of unfaced blanket on top of the faced insulation. Sometimes referred to as a “sag and bag” approach, here the first layer of insulation over the purlins is ordered to accommodate larger amounts of drape between the roof structure to permit another layer of unfaced insulation to be added on top. This increases the insulation thickness between the purlins but keeps it thin enough to be compressed to accommodate the roof panel installation. For coordination purposes, the thickness of this upper insulation over the purlins needs to be known by the building manufacturer so the clips and fasteners can be properly sized. Likewise, the amount of insulation draping between the purlins needs to be known to determine if purling bracing or other accessories may potentially interfere with the insulation installation.

Other types of cavity fill system may include a faced batt or face roll insulation with long tabs, which are secured to the tops of roof purlins and nest fully into the purlin cavity to fill the space more effectively. This helps in eliminating greater compression of multiple layers of insulation on top of the purlins and permits an additional layer of unfaced insulation on top of the roof structures and/or a thermal spacer block. This system may also require some intermediate banding to support the insulation between the primary supports.

A liner system may be installed that employs a continuous vapor retardent material. This liner is secured to the bottom of the roof structure and additionally supported with metal banding allowing the cavity to then be filled with unfaced insulation between the purlins. More unfaced insulation can also be added on top of the purlins as well. In all of the cases where cavity fill systems are used, it is important to advise the building manufacturer/roof supplier which type is being used to ensure proper panel clip heights and screw lengths. This is important because these systems can and will interfere with the roof structural bracing making them more difficult to install. The metal building supplier may be able to offer bracing alternatives or remedies to eliminate some or all of the bracing that would otherwise be in the way when installing the roof insulation. There may also be suggestions on how to avoid impeding or penetrating the vapor barriers which could lead to condensation issues. Overall, it is best to discuss and coordinate all of these items ahead of time.

Rigid Board/ Composite Systems:

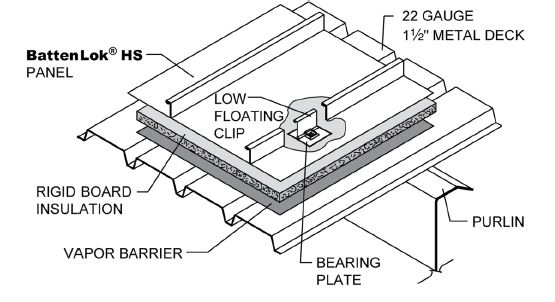

In this insulation approach, rigid foam insulation board is used to achieve the sought after energy performance. Commonly, these use metal deck panels over the roof structure thus supporting the insulation and a vapor retardant material on top of the deck. The insulation and the metal roofing can then be secured to the framing substructure or to the metal deck itself, which means the details of attachment need to be reviewed and engineered to avoid adverse affects on the roofing system.

Spray-on Insulation:

All of the above systems typically require attention to providing additional air and vapor barriers and proper cutting and fitting during installation so as not to cause unwanted infiltration or to prevent condensation from occurring. For these reasons and more, some people will consider the use of closed cell spray-on foam insulation, which can continuously provide all of these features in one product. It can also be installed after the roof is completed and structure is weathertight.

In the case of metal buildings, spray-on insulation is typically applied in the field onto the inside face of installed roof panels and sometimes wall panels too. There are, however, a few concerns with this approach in metal buildings. First, if conditions are not right and the panels are not properly prepared, then the spray foam can, in fact, trap moisture between the insulation and the metal components it is sprayed onto. That can lead to corrosion of the metal or deterioration of the insulation. Secondly, not all spray foams on the market are intended for this type of use so they don’t always adhere well to some metal panels, meaning it could become loose and fall away. Finally, continuous spray foam in this application will not always be able to expand and contract at the same rate that metal does. In some cases, that could mean that the foam suffers from differential movement causing it to break or lose adhesion.

For all of these reasons, be certain to research all options before considering or selecting a foam spray-on insulation that will not negatively impact your roof performance. If a foam insulation is preferred, it may be worth considering the use of insulated metal panels (IMPs) that are designed, engineered, and fabricated to be compatible with metal building construction.

Recognizing all of the above variations and options, the key point to remember about insulating metal buildings is the importance of communication between those designing and ordering an insulated metal building and those who are manufacturing and fabricating it. To find out more about the best ways to do that, contact your local MBCI representative.

In fact, engineered metal panel systems offer arguably the best possible continuous exterior system. Not only are they properly applied exterior to the building structure—outboard of columns, joists and girts—but they are also designed to ensure an

In fact, engineered metal panel systems offer arguably the best possible continuous exterior system. Not only are they properly applied exterior to the building structure—outboard of columns, joists and girts—but they are also designed to ensure an