Tag: commercial buildings

Level of Development (LOD) BIM Specifications for Metal Buildings

When designing and constructing metal buildings, an increasing number of professionals are using a computerized building information model (BIM) as their primary tool. This allows for detailed, three-dimensional computer models to be created, not only to develop the design, but to identify material lists, coordinate details, avoid conflicts between building systems and streamline the design and construction process.

Problem: BIM Coordination

Of course, design is a process that requires some back-and-forth between multiple parties to arrive at the best final solution. So, when a metal-building supplier or manufacturer is asked to provide their information to be incorporated into a BIM process, the question that naturally comes up involves the level of detail. This is common across all trades, and fortunately, there is an organization that is addressing this issue. Known as the BIMforum (www.BIMForum.org), is is the not-for-profit United States chapter of buildingSMART International, and its mission focuses on improving BIM technology, collaboration, education, innovation and open information exchange. As they describe themselves, “Co-sponsored by the Associated General Contractors of America (AGC) and the American Institute of Architects (AIA), BIMForum seeks to lead by example and synchronize with counterparts in all sectors of the industry to jointly develop best practice for virtual design and construction.”

Solution: Level of Development (LOD) Specification

A flagship publication of BIMForum is the 2016 version of Level of Development (LOD) Specification. Having evolved over several years, this publication is “a reference that enables practitioners in the AEC Industry to specify and articulate with a high level of clarity the content and reliability of Building Information Models (BIMs) at various stages in the design and construction process.” Coordinated with other industry standards, it “defines and illustrates characteristics of model elements of different building systems at different Levels of Development.”

Essentially, it defines and standardizes how much detail is expected in a building information model at different stages of design development. Therefore, if a metal-building manufacturer or any other trade is asked to supply its BIM information, then it needs to ask “What Level of Development?” so that is it providing the right amount of information to coordinate with the larger computer model for the building.

How LOD Works:

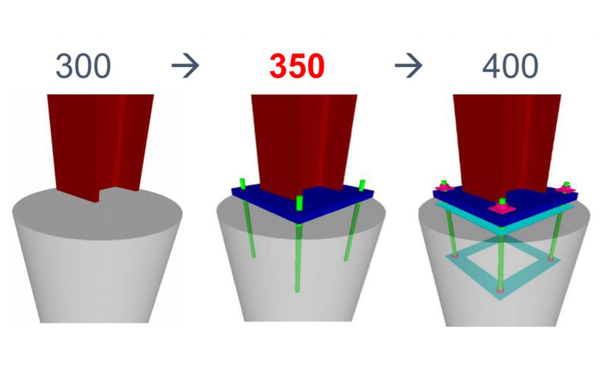

The LOD Specification is based first on the familiar Uniformat specification sections used by most spec writers. Metal Buildings commonly fall under Special Construction in Section F1020.40 in the Uniformat approach, or 21-06 10 20 40 in the Omniclass approach, and are found that way in the LOD Spec. From there, five levels of detailing are described by the numbers 100, 200, 300, 350 and 400, as described further below.

- LOD 100 – This is the most basic of model, described as “Generic mass of special structure with system typically noted with a design narrative for conceptual pricing.” It is likely that this level of BIM is already developed by an architect or engineer and given to a manufacturer or supplier as a starting point.

- LOD 200 – This level calls for basic primary structural member sizing, generic representation of secondary framing, and general cladding and exterior trim to be provided, including openings.

- LOD 300 – More-specific sizing of all needed primary frame structural members, web tapers, frame connections and similar details are called for at this level. Similarly, secondary framing needs to be shown, including purlins and bridging, girts, subframes and base conditions. Exterior panel and trim with actual profiles, actual openings and all significant trim and accessories are shown here.

- LOD 350 – This level starts to show coordination with other elements or building systems. Therefore, for the primary structure, things like base plate locations, bracing/gussets, clips and any reinforcement all need to be included. Secondary framing elements need to include similar details, such as nested members, connections to primary structure, any miscellaneous or secondary steel members, bridging, etc. Cladding and exterior trim would include all actual profiles, closures, downspouts and all minor trims shows at least generically.

- LOD 400 – This is the full-fabrication level equivalent to shop-drawing level of detail. As such it includes all final details, including welds, bolts, holes, cinching and all other details of fabrication and assembly for primary and secondary framing, plus all cladding and trim.

By using these standardized Levels of Development, all design and construction professionals can proceed in an orderly sequence to provide the appropriate information, receive coordination feedback and then move on accordingly to the next level.

The full 2016 LOD Specification can be downloaded for free at http://bimforum.org/log/. The specific information for Metal Building Systems can be found on pages 177–186. For information on how to work with a manufacturer to provide the appropriate BIM information, contact your local MBCI representative.

Evolution of the Metal Building Components Industry

Metal building components have been in use ever since iron and steel became commonly available during the 1800s. However, coordinated metal building components as we know them today really got their start during the 1900s, with a lot of significant developments happening just in the past 40 years. Here’s a quick overview:

1970s:

During the 1970s, the emerging metal buildings industry was primarily focused on providing pre-engineered solutions for commercial, industrial, and agricultural customers, mostly in the range of 10,000-square-foot buildings or less. The use of lighter-weight, tapered-end steel sections and bolted end-plate connections was beginning to be developed for widespread use, based on industry research. The development of technology that allowed for new methods of steel fabrication created growth for existing companies and helped new ones to form, such as MBCI in 1976. The energy crisis of the time brought interest in creating better insulation solutions.

1980s:

This was a period of growth along with the rest of the construction world. New plants and facilities were opening up in response to growing customer and market needs. New coating technologies were coming available that provided better corrosion resistance and allowed for more customers to consider using metal buildings. Technical research into wind loading for walls and wind uplift for roofs brought updated means and methods to address these critical structural engineering conditions.

1990s:

During this decade, the volume of metal buildings and tons of steel processed nearly doubled. More building types were being constructed out of metal building components as architects, engineers, and owners saw the flexibility, time savings, and cost efficiencies involved. Retail facilities, offices, even schools started to incorporate metal buildings and their components into their planning and construction. With this growth and expansion, technical issues such as snow loads and employee issues such as OSHA regulations were hot topics of research and focus.

2000s:

With strong momentum and growing success around the country, the industry began to offer more-diverse product offerings and components. Insulated metal sandwich panels with both interior and exterior finishes became more common. New roofing finishes and appearances became available. Structural research into seismic effects on metal buildings was conducted in response to California earthquakes, and solutions were determined. Further work was done on energy performance of metal buildings in response to energy codes and customer requirements. Additional work was undertaken on updated engineering guidelines for tapered structural members and exterior wall and roof finishes and styles. This included the use of horizontal instead of vertical siding systems and smooth-surface solutions.

A Look at Today in the Metal Building Components Industry:

The metal building industry has clearly evolved and come a long way from somewhat humble beginnings. Today, full systems or components can be found in a wide range of buildings types, creating highly attractive solutions that are often not recognized as metal buildings. Continued industry research helps manufacturers provide high-quality products that meet the demands of the larger building industry. Continued collaboration and partnerships are helping to foster diversified product offerings and new market penetrations. Overall, the past 40 years or so have been just the beginning – the future of the industry looks strong, and prospects remain high for continued growth.

Metal Roofs and Solar Energy: An Ideal Match

Everyone is talking about—and doing something about—sustainability. Metal roofs fit nicely into the sustainable-material equation because of their myriad traits, such as recyclability, reflectivity, longevity and durability. Another major component in the sustainability equation is renewable energy—the production of energy from renewable resources like sun and wind. A metal roof is the ideal location for solar energy production on homes, commercial buildings and recreational applications.

Why Solar Panels and Metal Roofs?

One of the key factors for long-term success of rooftop solar energy is the quality of roof under the solar panels. Roofs under photovoltaic (PV) systems should be durable and have an equivalent service life to the solar panels. However, too many traditional roof systems do not have a service life that matches, let alone exceeds, the service life of the PV panels. This is where metal roofs excel.

Service Life of Metal Roofs

A study of roof system longevity presented at the Fourth International Symposium on Roofing Technology by Carl Cash, a principle at Simpson Gumpertz & Heger, showed that metal panel roofs have the longest service life when compared to asphalt-based roofs and single ply roofs. The study showed that the average life of metal panels is 25 years. BUR and EPDM were second and third, respectively, at 16.6 and 14.1 years of average service life. Exceeding the Cash study, a more recent study conducted by the Metal Construction Association (MCA) and Zinc Aluminum Coaters (ZAC) Association showed the longevity of low-slope unpainted 55% Al-Zn alloy coated steel standing seam roofing (SSR) systems is 60 years.

Service Life of Solar Panels

Solar panels will last 25 to 30 years. In fact, some of the very first PV panels from the 1960s and 1970s are still producing energy. While their efficiency might decrease over time, solar panels will make electricity for many decades. For the most cost-effective rooftop solar energy installation, the longevity of the roof should be equivalent, or greater, than the solar panels so that the roof doesn’t need replacement during the life of the solar energy system. Metal panels are the most reliable, long-term roofing system for solar energy installation projects.

Built to Last

Simply put, installing solar energy on rooftops that don’t have an equivalent service life is a mistake, especially for solar projects that cover a large portion of the rooftop. The cost of decommissioning, removing, and replacing rooftop solar energy can cost 20% to 100% of the original installed cost. The cost tends to align with the percentage of rooftop covered with solar panels. Much of the cost to remove and reinstall is labor, but an older solar energy system will likely need some new components—most likely new wiring—when reinstalled, also adding to the cost.

Rooftop solar installations continue to grow year over year. And with the extension of the federal investment tax credit for five years, expect more solar energy installations on roofs. Pair solar energy with a metal roof, and you’ve hit a sustainable “home run.”

Learn other ways to implement Net-Zero Energy strategies into your building and learn how MBCI’s products contribute.