In a prior blog post, we introduced the capability of ordering metal roof and wall panels, trim and building components online using the MBCI online ordering website. While most people are familiar with ordering products on the internet from a list of standard offerings, there is another exciting aspect to these sites–custom items can be ordered online too! That means instead of needing to call or meet in person to place a custom order with a sales rep during business hours, custom trim and structural products can be ordered online anytime. Here’s how it works.

When Standard Isn’t Enough

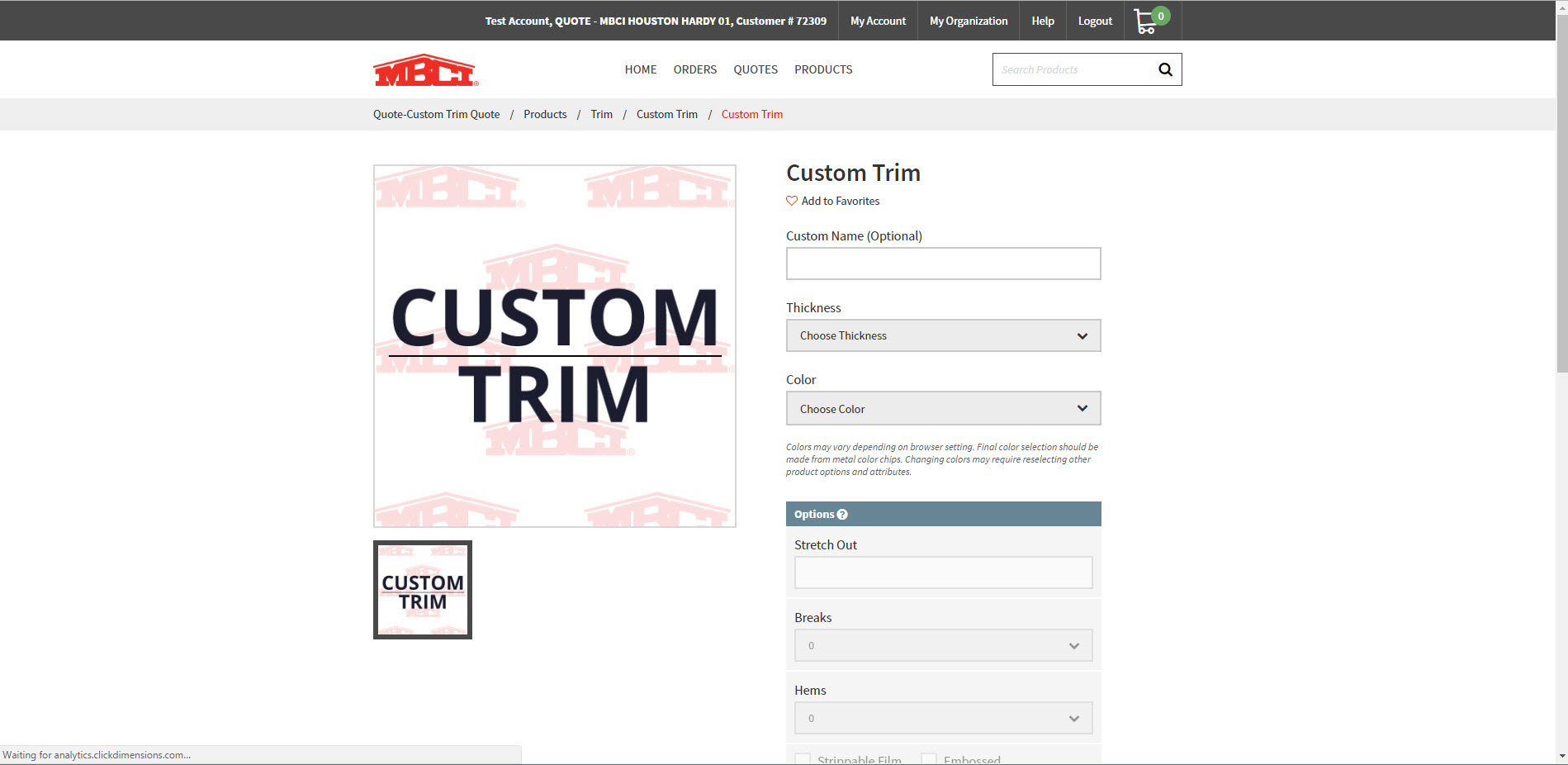

Most companies with online ordering websites offer products in standard shapes and lengths. Recognizing that not every job is standard, the MBCI online ordering website offers customers the ability to order custom trim and structural products online 24/7. Using the dedicated “Custom Trim” or “Custom Structural” product categories, you can select the type of trim or structural product you want and indicate all of the specifications desired. These include steel thickness, color, stretch-out (the width of the material before it’s bent), breaks needed in the trim, hems and other features.

Visualizing Custom Products Online

Even with the ability to set custom specifications, sometimes visuals are needed to ensure products are manufactured correctly. MBCI takes product customization a step further by enabling you to add hand-drawn or drafted drawings to show the complete layout of the product as a supplement to the selected specifications.

If drawings have already been prepared, they can be easily uploaded and linked to your MBCI order in any common electronic file format. If drawings aren’t already done, MBCI’s online ordering website provides an easy-to-use template that walks you through how to create simple hand-drawn or digital drawings.

A Time-Saving Process

Once all of the custom information is entered for your product(s) and you’ve reviewed for accuracy, simply add the item(s) to your cart. This process can be repeated for as many custom trim and structural products required. Additionally, you can save each custom item you create with it’s own product name to quickly add them to future orders.

Online ordering tools that offer a quick and seamless way to include custom trim and structural products in addition to standard items can save you time and help your business run more efficiently. The ability to customize products online makes it significantly easier to do business with the material supplier, particularly since most other online tools only allow standard products to be ordered.

To find out more about how to quote, order and build custom and standard products online, visit http://www.mbci.com/shop or contact your local MBCI representative to get signed up today. To be the first to know when we launch new time-saving enhancements to our online ordering tool, stay tuned to our blog, email and social media posts. Upcoming features include the ability to:

- copy and merge items from multiple quotes onto one,

- edit multiple items at one time,

- add entire product packages (assemblies) based on building specifications,

- and more!