Best practices for roofing contractors, general contractors…and even architects—from spec’d work to pre-roofing conferences.

Many metal roofs have roof penetrations for accessories installed by other trades. Unfortunately, oftentimes, these penetrations are improperly made or the accessory material is incompatible with the standing seam roof. A properly installed Galvalume standing seam roof, for instance, can be expected to last 60 years or longer. However, improper work on the roof by other trades can result in leaks and possibly a roof service life far less than 60 years. In order to achieve the best results, the roofing contractor needs to coordinate with the general contractor, the architect, and the building owner to ensure proper installation.

In most cases, it is the roofing contractor who is held responsible for all things roof! If armed with a clear checklist as he or she walks into a pre-roofing meeting with the architect, there will be a significantly greater likelihood of a well thought out and successful process. Here are some suggestions for the roofing contractor (in conjunction with the entire team) to consider.

- A reminder to specifiers to put in the project specifications that all roof penetrations and roof accessory installation must be coordinated with the roofing contractor. Beyond the obvious issue of maximizing performance, if a manufacturer’s weathertightness warranty is specified, the roof manufacturer must preapprove any work performed on the roof by other contractors.

- If the above is not in the project specifications, the roofing contractor should initiate the conversation during the pre-roofing conference with the architect and the general contractor.

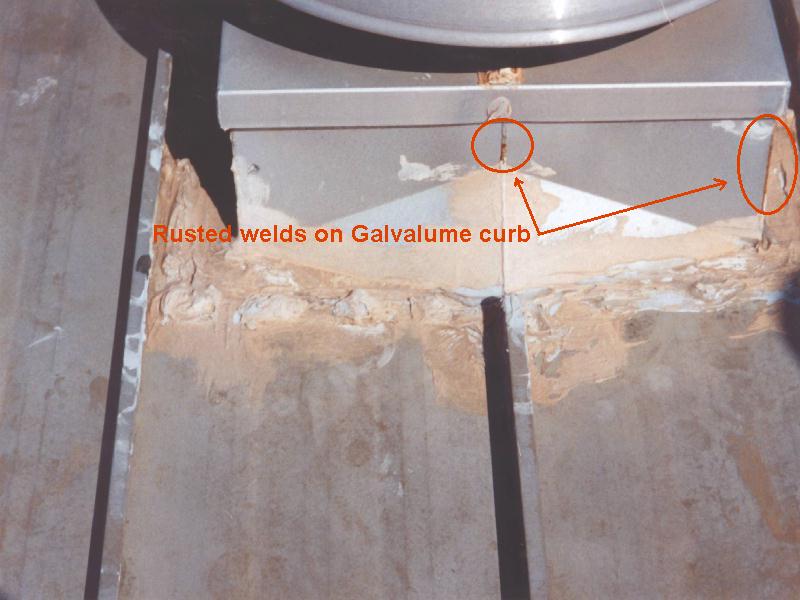

- Roof curbs should ideally be supplied by the roofing contractor and they should definitely be installed by the roofing contractor. Welded aluminum curbs should be used as specified by the roofing manufacturer. See tips for installing roof curbs, here.

- Pipe penetrations for vent pipes, heater flues, gas and electric, etc. as well as penetrations associated with lightning protection air terminals and cable management should be coordinated with the roofing contractor and with the roofing manufacturer if there is a weathertightness warranty. Rubber roof jacks should always be used.

- Ensure that dissimilar materials such as copper, lead, and graphite are not used on the roof. This includes treated wood, which contains copper. Condensate from roof top AC units must be piped off the roof as it contains dissolved copper.

- The roof must be protected from spills of any harmful chemicals or masonry products.

The above represents just an overview of some of the best practices the roofing contractor should consider when entering into a job with other trades. As the roofing contractor, anything that involves the roof will likely be seen as YOUR purview. After all, if there’s a leak, who are they going to call? That said, being proactive regarding roof accessory installation—regardless of who is doing the actual work—will serve all parties in the end. Get in front of any potential issues and ensure everyone is reading from the same playbook. For more information, contact your local sales representative.