Insulated metal panels (IMPs), a type of lightweight factory-fabricated metal panel, are a compelling alternative to more conventional roof panel choices. IMPs have a continuous insulating core that works together with metal skins to create a barrier against air, water vapor, and thermal conditions. One major benefit of IMPs, is their thermal efficiency, averaging R-7.0 to 7.2 per inch as compared to R-5.6 per inch for unfaced urethane board stock. Insulated metal roof panels are commonly available in thicknesses ranging from two- to six-inches which generally correlates to R-14 to 42.

Structure of IMPs

IMPs consist of two single skin metal panels and a foamed-in-place core. The foam insulation is made of non-chlorofluorocarbon (non-CFC) polyurethane foam. As an example, MBCI’s IMPs consist of closed cell structure and nominal density of 2.2 pounds per cubic foot. Its closed cell structure also prevents the foam from absorbing water.

Thermal Bow in IMPs

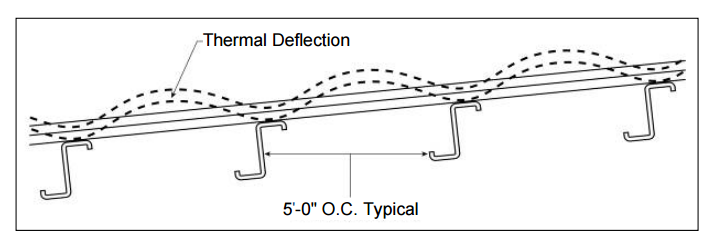

An interesting phenomenon with IMP roof panels is that you don’t have to deal with thermal expansion the way you do with single skin panels. On wide, through-fastened roofs, you can have issues with panels slotting around the fasteners. And with standing seam roofs, you have to ensure that the panel clips can handle the anticipated thermal movement. However, insulated panels experience something called “thermal bow.”

An IMP’s exterior metal skin will still expand as it heats up. But, instead of causing the whole IMP to grow in length, the exterior skin of the IMP will bow up slightly between purlins/joists because the interior metal skin of the IMP maintains a relatively constant temperature. The insulating foam that adheres to this metal skin flexes to allow for this bow. Because of this, thermal expansion is accommodated by the small incremental growth (and bowing up) of the exterior metal skin between each purlin/joist, which are usually spaced five to seven feet apart.

Conclusion

Insulated metal roof panels are fixed roof systems that will experience thermal bow between the purlins as opposed to single skin systems, which are designed to allow for expansion and contraction in the panel. With its thermal efficiency benefits, IMP roofs are beginning to get noticed as an alternative for designers looking for a progressive choice to achieve flexibility and function.