As is often the case when it comes to your investments, it’s always a good idea to diversify. This also applies to the investment of your construction expertise as a roofing contractor. Even with the mild uptick in new construction activity of late, contractors are smart to explore the additional revenue stream that can come from roof renovations and retrofits.

Most metal roof retrofit work entails adding slope to an existing flat- or low-sloped roof. According to a 2013 article in Metal Construction News, about 25 percent of U.S. commercial, institutional and public buildings are 55 years old or older and consist of flat-roof stock that has reached the end of its service life. Two years later, that percentage is surely higher.

Most metal roof retrofit work entails adding slope to an existing flat- or low-sloped roof. According to a 2013 article in Metal Construction News, about 25 percent of U.S. commercial, institutional and public buildings are 55 years old or older and consist of flat-roof stock that has reached the end of its service life. Two years later, that percentage is surely higher.

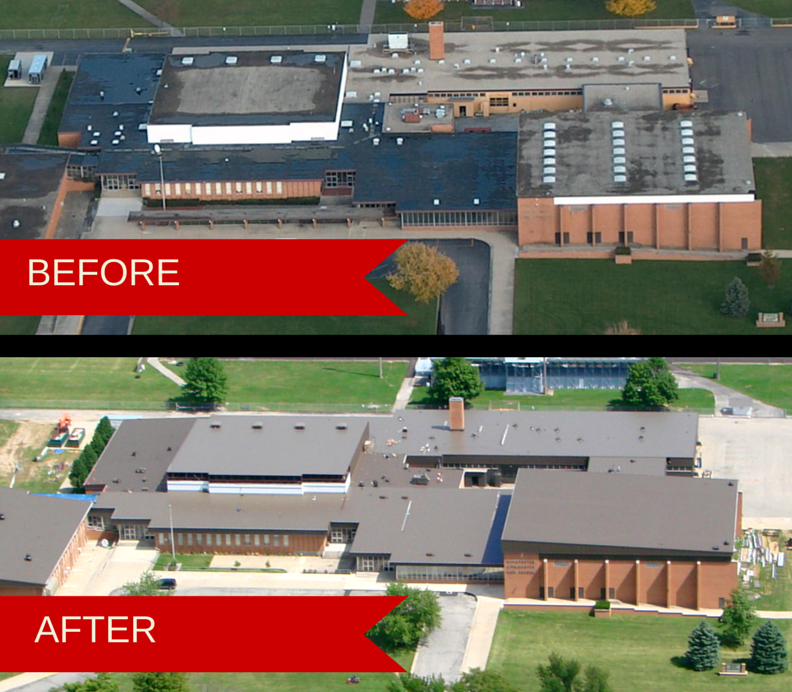

To transition from a flat roof to a sloped roof is a good move, because it will result in lower energy and maintenance costs for years to come. It is also environmentally smart, because metal is one of the most recycled materials used in construction, and metal roofing is 100 percent recyclable at the end of its service life. A metal roofing system provides for additional insulation, as well as the installation of solar panels that reduce reliance on electricity. And in most circumstances, a new metal roof can be installed without having to remove the existing flat roof. A metal retrofit may carry a higher initial cost, but when total life-cycle cost is considered, a metal retrofit will end up being the lowest cost alternative.

A large number of buildings with flat membrane or built-up roofs require a framing system to produce an adequate slope. But this particular type of retrofit can be challenging. In general, the retrofit market is more specialized and much more technical than what roofing contractors are likely used to in the existing metal building market. At the same time, the retrofit market can be very profitable and is worth getting up to speed on.

Whether you’re doing a small retrofit project or a complete renovation, MBCI can assist you with developing a preliminary budget, estimating, engineering, as well as providing a complete set of shop drawings for your retrofit project.

Stay tuned for future posts where we’ll provide some guidelines on how to successfully navigate the design process of retrofitting a flat or inadequately sloped built-up or membrane roof. Adding this diversity to your portfolio of roofing skills will likely net a high return on investment.