Metal roofing has always been a trusted choice for durability, energy efficiency and aesthetic appeal. But as the construction industry evolves, so do the expectations for roofing systems. In 2026, metal roofing is no longer just about strength. It’s about sustainability, smart technology and design innovation. Whether you’re an architect, contractor or building owner, understanding these trends will help you stay ahead of the curve.

1. Sustainability Takes Center Stage

Environmental responsibility is now a driving force in construction decisions. Metal roofing already offers significant sustainability benefits, including recyclability and long lifespans, but the industry is pushing even further. Here’s what to expect:

- High Recycled Content: Metal panels can be manufactured with a high percentage of recycled content, helping reduce the overall carbon footprint of production.

- Cool Roof Coatings: Reflective coatings help reduce heat absorption and lower energy costs for cooling.

- Solar Integration: Roofing systems designed to accommodate solar panels seamlessly are gaining traction, making renewable energy adoption easier for building owners.

These advancements not only help building designs meet regulatory requirements but also appeal to eco-conscious clients who prioritize green building certifications like LEED.

2. Bold Aesthetic Options

Metal roofing is no longer limited to utilitarian designs. Today’s options allow architects and designers to make bold statements:

- Expanded Color Palettes: Matte finishes, textured coatings and vibrant colors are becoming popular for modern aesthetics.

- Design-Forward Profiles: Panels featuring visually distinctive details such as pencil ribs, deep corrugations, and asymmetrical rib patterns enable creative architectural designs.

- Mixed-Material Looks: Combining metal panels with natural wood or stone accents creates visually striking exteriors that blend durability with natural beauty.

These design innovations make metal roofing an attractive choice for both commercial and residential projects where curb appeal matters.

3. Extreme Weather Performance

Climate change is driving more severe weather events, and roofing systems must adapt. Metal roofing is already known for its resilience, but manufacturers are enhancing performance even further:

- Wind Uplift Resistance: Durable fastening systems and panel designs improve resistance to hurricane-force winds.

- Impact-Resistance: High-quality steel provides protection against many types of common impact damage, helping minimize insurance claims and reduce repair costs.

- Fire-Resistant Systems: In wildfire-prone areas, metal roofing offers superior fire protection compared to traditional materials with organic components.

These improvements make metal roofing a smart choice for regions facing unpredictable weather patterns.

4. Energy Efficiency and Insulation

Energy efficiency remains a top priority for building owners. Metal roofing contributes to lower energy costs through:

- Reflective Surfaces: Cool roof coatings help reduce heat absorption to keep buildings cooler in summer.

- Insulated Panels: Combining roofing with insulation systems helps improve thermal performance and reduce HVAC loads.

- Ventilation Enhancements: Integrated ventilation solutions help maintain indoor air quality and temperature control.

As energy codes become stricter, these features will be essential for compliance and cost savings.

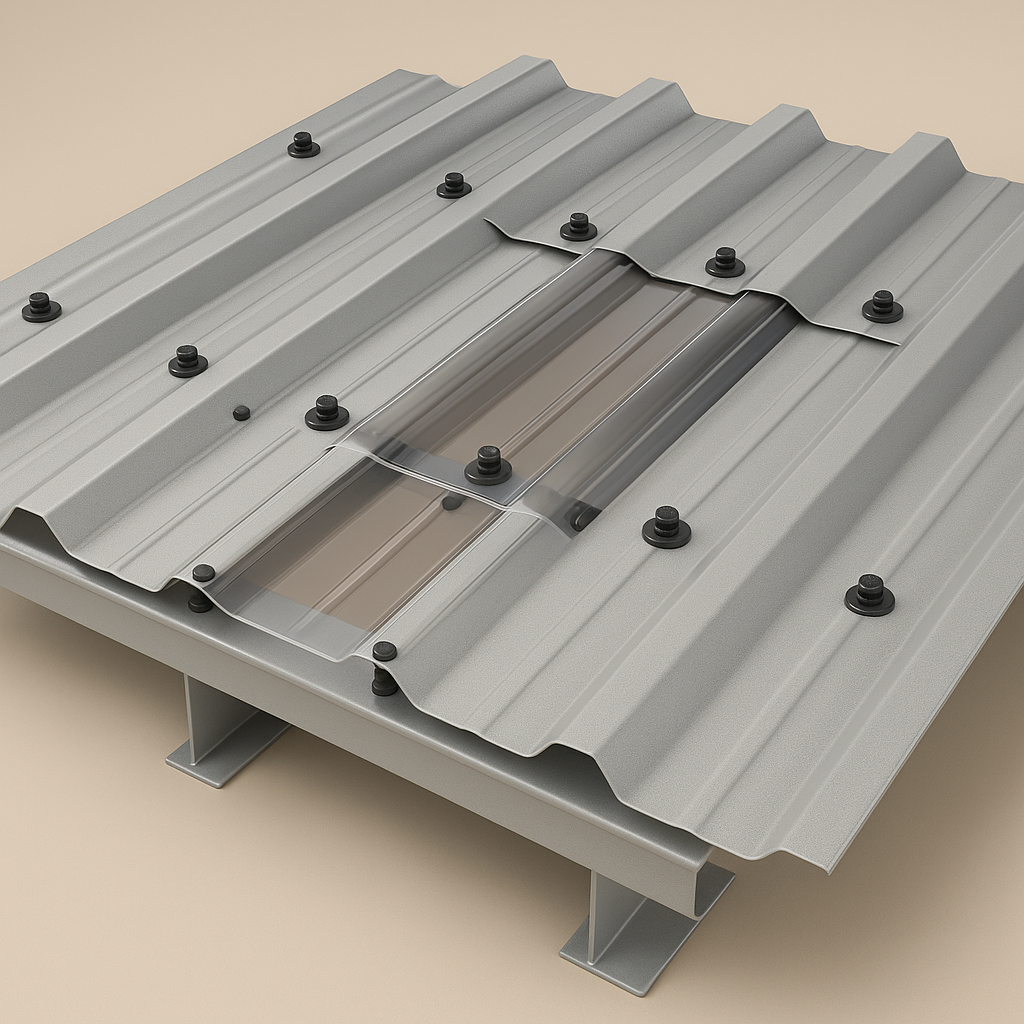

5. Modular and Prefabricated Solutions

Speed and efficiency are critical in today’s construction environment. Prefabricated metal roofing systems are gaining popularity because they:

- Reduce Installation Time: Pre-engineered panel and trim designs help simplify installation and minimize labor costs.

- Ensure Quality Control: Factory-controlled manufacturing help ensure consistency to reduce on-site installation issues.

- Support Design Flexibility: Modular systems can be customized for various building types and architectural styles.

This trend aligns with the growing demand for faster project delivery without compromising quality.

Conclusion

The future of metal roofing is bright and innovative. From sustainability and smart technology to bold aesthetics and extreme weather performance, these trends are shaping the next generation of roofing solutions. By embracing these advancements, you can deliver projects that are not only functional and durable but also environmentally responsible and visually stunning.

Ready to explore the latest metal roofing solutions? Contact MBCI today to learn how we can help you stay ahead of the curve.