The International Residential Code (IRC) is commonly considered to be a prescriptive code, which means there are many requirements included that provide specific directions. Prescriptive-based code language provides a simpler method of enforcement for inspectors. And shouldn’t that be the case for one- and two-family dwellings, where well built and affordable is the goal?

Underlayment Requirements

In Chapter 9 of the 2015 IRC, the underlayment requirements for steep-slope roof coverings are included in three tables—material types, application and attachment requirements. Each table includes specific information for metal panels and separates out high-wind areas (defined as greater than 140 mph, and is only in the southernmost portion of Florida).

Material Type Requirements

Underlayment types for metal panels needs to only comply with manufacturer instructions. D226 and D4869 underlayments are viable options, as long as metal panel manufacturers allow them. And very importantly for metal panels, synthetic- / polymer-based underlayments are a viable option, again, as long as the panel manufacturer allows them to be used.

For metal panels in high wind areas, only D226 Type II and D4869 Type IV are allowed. In other words, only the heaviest materials are allowed in the highest wind zones.

Application Requirements

Simply put, underlayment should be applied according to the manufacturer’s installation instructions. For high-wind areas, specific application requirements are provided:

“For roof slopes from two units vertical in 12 units horizontal (2:12), up to four units vertical in 12 units horizontal (4:12), underlayment shall be two layers applied in the following manner: apply a 19-inch strip of underlayment felt parallel to and starting at the eaves. Starting at the eave, apply 36-inch-wide sheets of underlayment, overlapping successive sheets 19 inches, and fastened sufficiently to hold in place. For roof slopes of four units vertical in 12 units horizontal (4:12) or greater, underlayment shall be one layer applied in the following manner: underlayment shall be applied shingle fashion, parallel to and starting from the eave and lapped 4 inches. End laps shall be 4 inches and shall be offset by 6 feet.”

Underlayment Attachment Requirements

Underlayment should be attached according to the manufacturer’s installation instructions. For high-wind areas, specific attachment requirements are provided:

“The underlayment shall be attached with corrosion-resistant fasteners in a grid pattern of 12 inches between side laps with a 6-inch spacing at the side laps. Underlayment shall be attached using metal or plastic cap nails or cap staples with a nominal cap diameter of not less than 1 inch. Metal caps shall have a thickness of at least 32-gage sheet metal. Power-driven metal caps shall have a minimum thickness of 0.010 inch. Minimum thickness of the outside edge of plastic caps shall be 0.035 inch. The cap nail shank shall be not less than 0.083 inch for ring shank cap nails and 0.091 inch for smooth shank cap nails. Staples shall be not less than 21 gage. Cap nail shank and cap staple legs shall have a length sufficient to penetrate through the roof sheathing or not less than 3/4 inch into the roof sheathing.”

Self-Adhesive Underlayment Options

Of course, there are exceptions to these requirements. The first is to use a self-adhesive underlayment (i.e., ice dam protection) over the entire roof. The material needs to comply with ASTM D1970, “Standard Specification for Self-Adhering Polymer Modified Bituminous Sheet Materials Used as Steep Roofing Underlayment for Ice Dam Protection” and be installed per the metal panel manufacturer’s requirements. The code also points out that roof ventilation must be considered because a self-adhesive sheet is most often an air barrier and a vapor retarder. Concerns with moisture are quite relevant when these types of materials are installed over the entire roof deck. The second exception is to tape the seams of the roof deck with 4-inch wide strips of D1970 material, and then cover the deck with underlayment. The second exception is not widely used, except when trying to reduce, or eliminate, air flow through the deck while allowing moisture to escape.

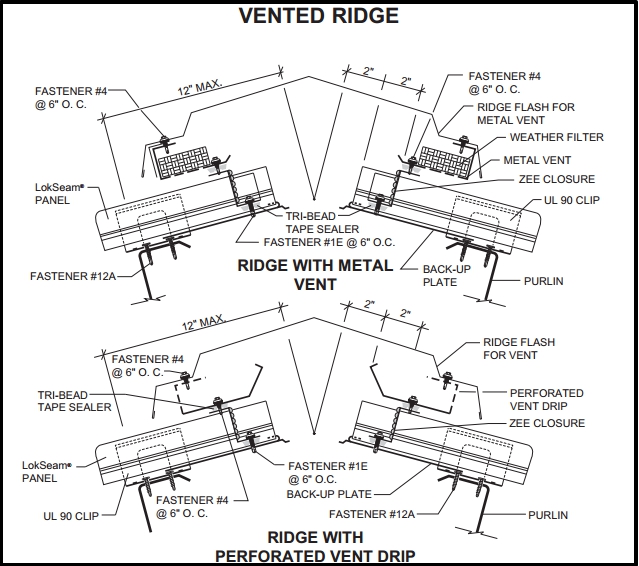

IRC Requirements for Attaching Metal Panels

The IRC also includes some, but not many, requirements for the attachment of metal panels. The IRC requires metal panels be attached per manufacturer’s installation instruction and “be secured to the supports.” This implies fasteners should be attached to purlins or rafters, but one could easily argue the roof deck is the support for the metal panels. However, the IRC does provide specifics for fasteners used to attach metal panels, but the following is only applicable if manufacturer’s instructions don’t include fastener requirements. The IRC states:

“In the absence of manufacturer’s installation instructions, the following fasteners shall be used:

-

Galvanized fasteners shall be used for steel roofs.

-

Copper, brass, bronze, copper alloy and 300-series stainless steel fasteners shall be used for copper roofs.

-

Stainless steel fasteners are acceptable for metal roofs.”

The Importance of Following IRC and Manufacturer Instructions

The IRC is a prescriptive code and there are many specific requirements for underlayment and metal panels. But because of the wide variety of styles, the IRC appropriately requires installation according to manufacturer’s instructions. It’s important to specify a new roof using both manufacturers’ instructions and IRC’s specific requirements. And, remember, a metal roof will have a long service life, so the underlayment’s service life should equal that of the metal roof. Don’t be shortsighted when designing for longevity.