Traditionally, when we talk about metal products for self-storage facilities, we think about the metal building panels used for exterior wall and roof systems. But, when considered holistically along with interior components such as roll-up doors and hallway systems, the wisdom for contractors and erectors of turning to a single-source supplier comes sharply into focus.

There is, perhaps, some “old habits die hard” thinking behind customers traditionally sourcing interior and exterior components from different suppliers. This has meant that self-storage unit doors and hallway systems or the non-load bearing components inside of a building have generally been sourced from someone other than the company that manufactures the exterior building materials. But, just because this is how it’s been done in the past doesn’t mean it’s the best way moving forward. In fact, utilizing a single manufacturer able to offer a comprehensive, full-scale system—that is providing both exterior building solutions and interior self-storage solutions—can bring untold benefits to a project.

Advantages of Single-Source Provider for Self-Storage Facility Contractors and Erectors

One way to think about the benefits of using a single-source building material supplier for self-storage facility development is with a simple analogy to a consumer buying a car. When you set out to purchase a car, what if you had to buy the body of a vehicle from one dealer, but then you buy the engine, tires, seats, steering wheel, brakes and headlights from all different shops? That would be a rather cumbersome process. In reality, when we buy a new car, we can select the model we want and specify the options we want included—knowing that all the parts and accessories needed to provide the end-result are included when the car is delivered. So, you ultimately deal with one source, one contract and one purchase order to get the complete package.

Similarly, a reputable single-source supplier can help simplify the process needed to develop self-storage facilities. Contractors and erectors can get the materials and resources they need by working with a single point of contact at the single company, thereby streamlining the material ordering and delivery process in alignment with their construction needs and schedules.

With complex projects in mind, an experienced single-source vendor strategy drives successful outcomes and mitigates risk, but no one entity can do everything on its own. Therefore, an ideal vendor needs to have additional, seamless partnerships requiring specific expertise and certifications.

Lead-time and Optimal Delivery

The timing of material delivery can make or break construction schedules and budgets. In this industry, the quicker a building owner can get a facility open and start collecting rent/fees from customers, the greater the financial benefits will be.

When a manufacturer supplies all building materials for a project, they are able to build a relationship with the contractor or builder and optimize the support they provide on projects. This in-depth knowledge of all aspects of the project allows for a single-source manufacturer to ensure materials don’t show up too early, which can cause storage issues on the job site, and also keep them from arriving too late, preventing costly labor issues.

To guarantee reliable delivery, a single-source supplier can address industry concerns related to capacity by optimizing production methods and resources to handle spikes or drastic upticks in workload. Ideally, this would result in leveling off to a two- to three-week lead time rather than the typical eight-week lead time for delivering material you’d see on a given self-storage project.

Buying Power

Working with a single-source manufacturer leverages bulk buying power to ensure materials are sourced at the best rates possible. This cuts down on the time spent negotiating material costs with other manufacturers and suppliers. In addition, using a single-source supplier means spending less time finding and managing vendors and more time servicing your customers.

Material Compatibility

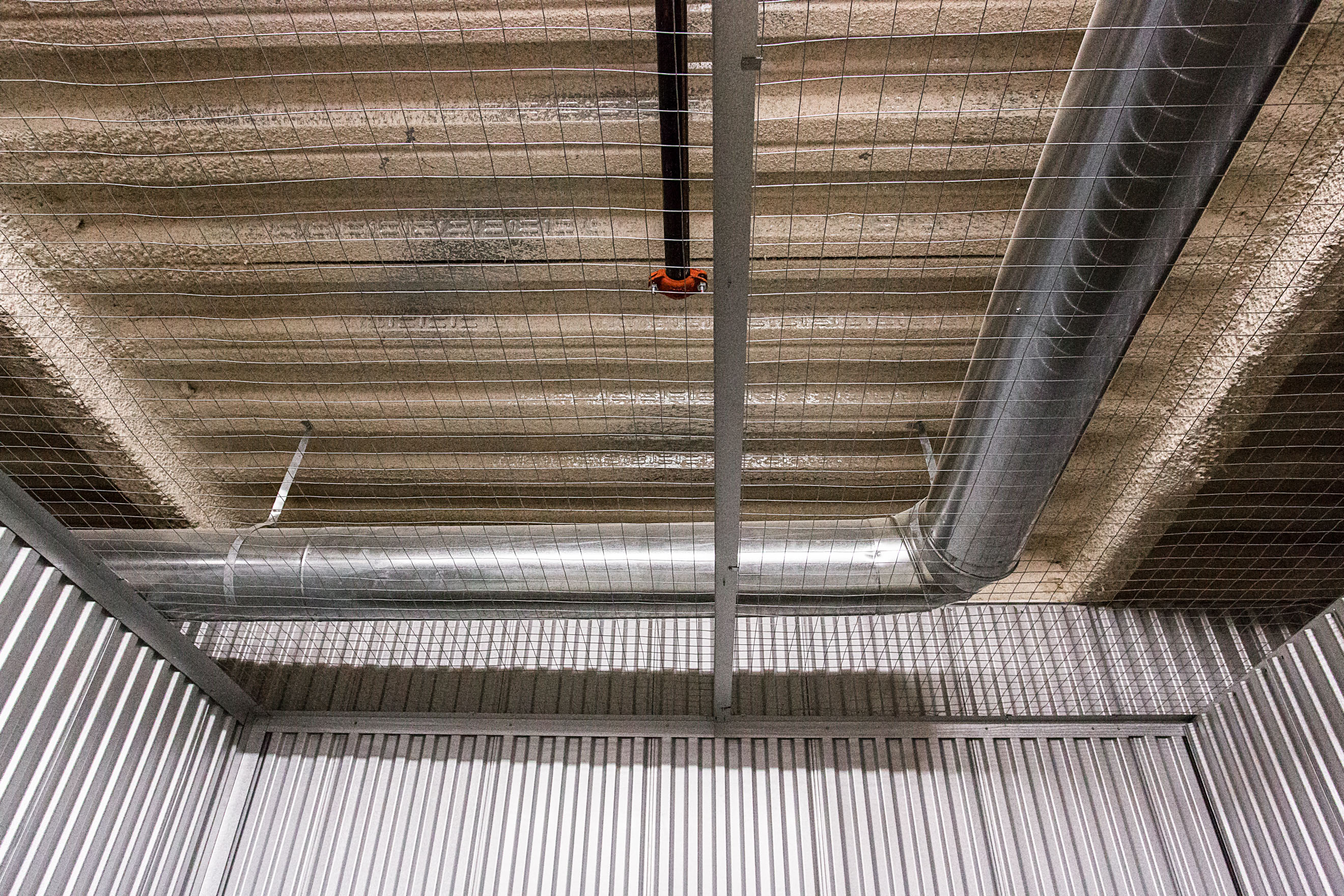

Another key benefit to using a single source for self-storage facility development projects is the inevitability of fewer potential product compatibility issues than might be experienced when sourcing different materials from several different manufacturers. By turning to a manufacturer that is essentially providing an envelope solution for self-storage facilities—not just a single part that must coexist with another manufacturer’s part—that expertise will help ensure all materials work together seamlessly and not jeopardize the build.

To learn more how MBCI can be a single-source for your self-storage facility project, contact your local MBCI representative.