- Products

- Industries

- Project Gallery

- Resource Center

- Metal Institute

- Services

- Shop

- Contact Us

May 16, 2016

by Jason Allen

Among the most important factors to account for when specifying a standing seam metal roof are wind control and wind uplift. It is imperative to take the necessary measures to ensure the safety and efficacy of the metal roof. The wind clamp—an extruded piece of aluminum that is placed on the panel seams at clip locations—is one accessory that can be used to improve wind uplift characteristics on metal roofs, delivering substantial time and cost savings as these devices help mitigate risk of wind uplift and improve overall wind design.

A typical failure mode of a standing seam metal roof panel is the clip top pulling out of the panel seam when the panels are subjected to high winds. With a standard install of a standing seam panel, the seams just fold into each other. With enough pressure, wind will force seams to come apart—be it a vertical failure, horizontal movement of the seam or from clip disengagement. The clip top can then pull out of the panel seam.

The wind clamp resists the panel seam being opened, allowing for higher uplift loads. The purpose of wind clamps, in fact, is to prevent  failures at the seam openings due to any deflection of the panel. The wind clamps provide more strength, thereby dramatically improving wind uplift performance.

failures at the seam openings due to any deflection of the panel. The wind clamps provide more strength, thereby dramatically improving wind uplift performance.

The clamp is installed over the panel seam at clip locations, in the edge and corner zones of the roof. This allows the roof to resist the higher wind pressures in these zones, usually eliminating the need for additional purlins or joists. On large roofs, the savings can be substantial.

Another benefit is shorter installation time. Since additional purlins or joists are typically not required at the edge or corner zones of the roof, the building can be erected faster.

When choosing the type of wind clamp, it is important to consider the type of panel and the special features of the clamps. MBCI, for example, uses S-5!’s patented wind clamps, which work for two panel types—Ultra-Dek® and Double-Lok®. The S-5! wind clamps do not penetrate the steel, thereby eliminating the risks of corrosion and water leakage that can be introduced by a hole in the steel. Since the screws are hidden from the weather elements, it helps to maintain waterproofing.

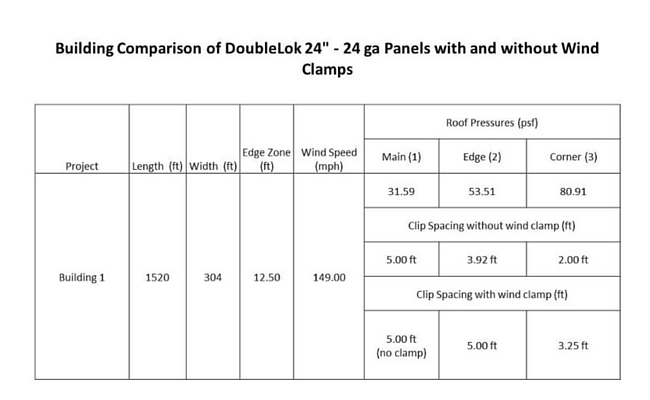

One of the biggest benefits of using wind clamps in the edge and corner zones is that usage minimizes the quantity of purlins needed, resulting in substantial cost savings. For example, let’s look at a comparison using MBCI’s Double-Lok 24” – 24 ga. panels with and without wind clamps.

In this example:

Utilizing wind clamps to protect the investment of a standing seam metal roof can increase strength, make installation faster and lower overall cost.