- Products

- Industries

- Project Gallery

- Resource Center

- Metal Institute

- Services

- Shop

- Contact Us

February 28, 2022

by MBCI

Buildings usually need new or replacement roofing installed at some point during their service lives. New metal roofing is an ideal roofing retrofit option due to its longevity and durability, which can extend the life of the roofing and require fewer replacements over time. The aesthetic appearance of a new metal roof can also make a notable visual impact to upgrade the building itself.

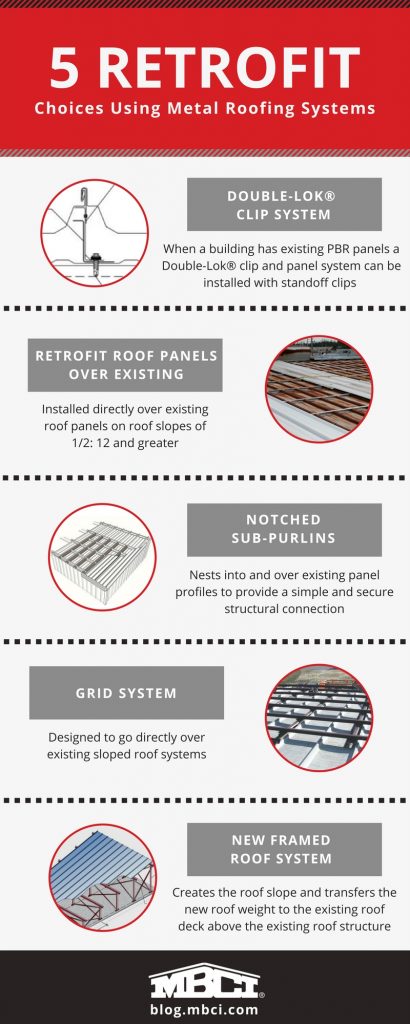

There are several types of metal panel systems that can be used for a roof retrofit on an existing building. Here is a quick look at five different options that can be selected from and tailored to suit a particular building. Since all of them will add some structural loading to the roof, all the retrofit solutions should be reviewed by a professional structural engineer to be sure the existing building can accommodate the changes.

When an existing building has an existing PBR roof panel or similar, a Double-Lok® clip and panel system can be installed directly over the existing roof with minimal alterations. In this case, 2″ standoff clips are run from eave to ridge and fastened through the existing roofing panels down into the existing purlins. The new standing seam metal roofing panels are installed along these clips, so they are held 2″ above the purlins and 3/4″ above the major ribs of the existing panel roof.

Because of these clearances, the cavity between the old and new roofs can either be vented or additional insulation can be added. Venting the cavity can be a good option when the existing roof slope is 3:12 or greater, as this allows for convective airflow during the summer and can help reduce the chance of ice damming in the winter.

For any slopes of 1/2: 12 or greater, adding insulation can improve the overall thermal performance of the building. Generally, this system allows for considerable versatility, even if it takes more parts and labor than some other solutions.

Check out our installation video to learn more!

For cases where a standoff isn’t sought, new, non-structural metal roof panels with a specifically retrofit profile can be installed directly over existing roof panels on roof slopes of 1/2: 12 and greater. That means there is no need to tear out the old roof, since the new panels are through-fastened into the old ones and the purlins below, all in a pattern that avoids the original fasteners. Such retrofit panels are available in 29 and 26 gauge in full range of colors and come with a factory-applied vapor barrier on the underside. Even light-transmitting panels are available for this retrofit panel system.

A variation on the metal-over-metal roofing approach is to use specifically designed z-purlins with notch-outs that are screwed down to the existing purlins.

Unlike other systems that run retrofit support members from the eave to the ridge, the notched purlins run parallel to both (in line with existing purlins) with the notches spaced to clear the ribs or corrugations in the existing metal roofing.

MBCI has several roof panels available to match virtually any metal roof produced in the last 50 years. That means they can be installed over existing roofing and, in the process, provide enhanced structural capabilities because of the added sub-purlins.

When an existing purlin spacing doesn’t meet current code requirements, then the use of crisscrossing hat sections in a grid pattern can provide the additional support needed. Such grid systems are designed to go directly over existing sloped roof systems, but many require the use of specific metal roofing panels to work properly.

In some cases, a full, steep-sloped roof (greater than 4:12) is sought to be installed over a low-slope roof (1/4:12 – 4:12). In this case, a full metal framing system is available that will create the desired roof slope and transfer the new roof weight to the existing roof deck above the existing roof structural members. As such, the coordination of the new system with the existing roofing, insulation, and structure needs to be addressed by licensed engineers.

Once designed and installed, an “attic space” will be created by the new retrofit roof system, which should include proper venting in accordance with applicable codes, allowing trapped moisture to escape. It is also recommended that such “attic space” be reviewed by other building, fire, or insurance-related officials for possible sprinkling or extension of existing firewalls to the bottom of the “new” roof system. Regardless, a minimum of 3″ vinyl-faced roll insulation between the retrofit panels and the retrofit purlins will help prevent condensation and roof noise in addition to improving energy efficiency.

To find out more about which retrofit options, or options, are best suited to a particular building that you are involved with, contact your local MBCI representative.

Check out the Metal Minutes Podcast to stay up to date on news and learn more about frequently asked questions!